Why is the the surface roughness of stainless steel tanks relevant?

The surface roughness of stainless steel tanks and vessels is a crucial factor for quality, hygiene, and compliance in various industries. Particularly in the food, pharmaceutical, and chemical industries, the roughness (Ra value) plays a central role: it primarily refers to all product-contact surfaces inside the tank, as these can significantly impact product quality. But what does surface roughness mean for tanks and vessels, how is it measured, and what standards need to be considered?

What does the Ra value mean for stainless steel tanks?

The Ra value (roughness value) indicates how smooth or rough the product-contact surface of a vessel is. It is measured in micrometers (µm):

- Low Ra value (e.g., ≤ 0.5 µm): Smooth surface, easy to clean, hygienically optimal

- High Ra value (e.g., > 1.0 µm): Rougher surface, harder to clean, higher susceptibility to deposits and residues

Therefore, when procuring a new or used storage tank or pressure vessel, the appropriate surface roughness (Ra value) for your intended use should be considered. This value can be precisely determined with manageable effort using a portable roughness measuring device.

What surface roughness is ideal for a tank?

The requirements for the surface roughness (Ra value) of a specific vessel or storage tank vary greatly depending on the industry:

Food industry: high hygiene standards play a central role

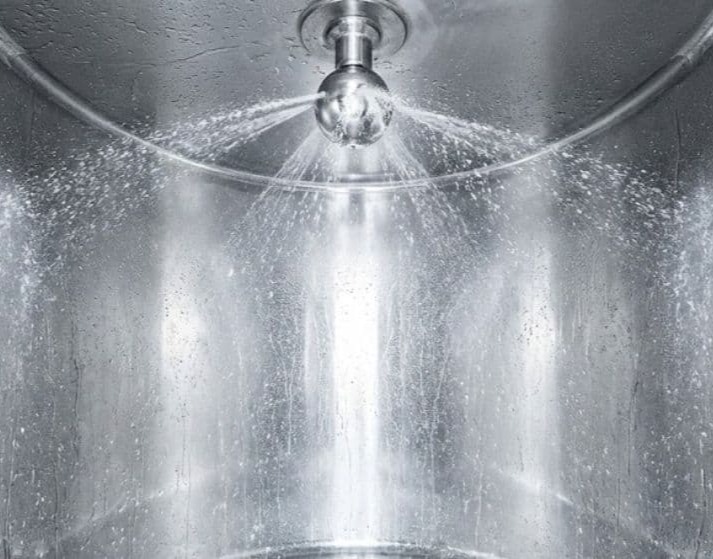

A smooth surface reduces the risk of contamination and facilitates regular CIP cleaning. Many regulations, including FDA and EHEDG guidelines, specify clear hygiene standards. Even if no explicit Ra value is required, Ra ≤ 0.8 has become a guideline and industry standard in the food processing sector (i.e. for processing or storing milk, fruit juice, liquids, or flavors).

Pharmaceutical industry: highest focus on contamination-free conditions through cleaning validation

In the pharmaceutical industry, even the smallest contamination is critically important for the product quality of active pharmaceutical ingredients (API), dietary supplements, or other medicines. Validated procedures and the highest manufacturing standards are implemented to minimize the risk of faulty batches. An Ra value of ≤ 0.5 µm or even 0.2 µm is often required in the pharmaceutical industry to meet the highest design standards. Depending on the application, electropolished stainless steel vessels may be required, which meet the highest standard for product-contact surfaces.

Chemical industry: corrosion protection and resistance are the main focus

In many areas of the chemical industry, the material's durability plays a more central role than minimizing surface roughness (e.g., organic chemicals, agrochemicals, lubricants). Often, product-contact surfaces in pickled and brushed condition are sufficient. However, in the field of specialty and fine chemicals, and some other product groups, there may be higher requirements for surface roughness – often ranging between 0.2 and 0.8 µm.

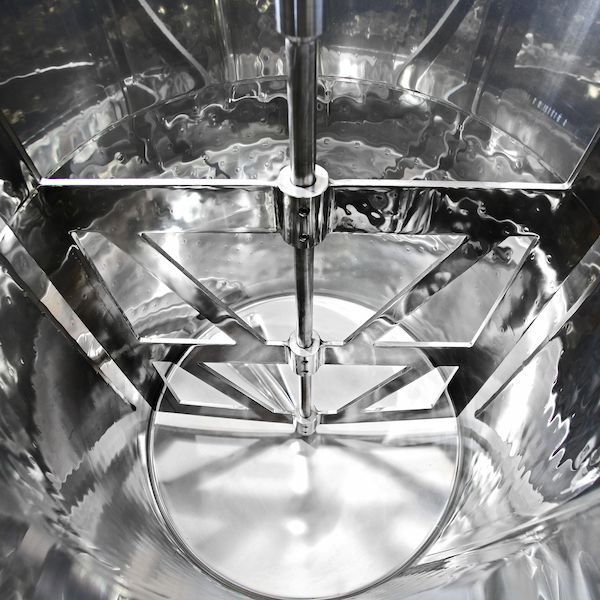

What procedures are used to optimize surface roughness?

Various processes are used to treat the product-contact surface of a stainless steel container:

- Mechanical processes:

- Grinding removes unevenness and creates a uniform surface.

- Polishing creates a mirror-smooth surface with Ra values below 0.2 µm.

- Chemical processes:

- Pickling removes impurities and increases corrosion resistance.

- Electropolishing improves chemical resistance and reduces the Ra value to as low as 0.2 µm.

- Coatings: Special epoxy or polymer coatings protect the inner surfaces of containers from chemical stress and prevent contamination.

Conclusion: the required surface roughness is determined by the hygiene requirements of the intended use

The choice of the correct Ra value when purchasing a stainless steel vessel is crucial for compliance with hygiene standards in a manufacturing facility. Different industries have different requirements. The highest standards apply in the pharmaceutical and food industries, where polished or electropolished surfaces with roughness of ≤ 0.8 µm are required. In the field of chemical raw materials and solvents, the material's durability is the primary focus, while surface roughness in the classic pickled and passivated process is often sufficient. Therefore, when purchasing a stainless steel tank, it is always advisable to also consider the required surface roughness. Especially in sensitive product areas, this is an important factor for meeting relevant industry standards, reducing maintenance costs, and ensuring reliable product quality.

Behälter KG Bremen – new and second-hand stainless steel tanks in all surface qualities since 1965

As a leading dealer for new and used stainless steel tanks, we offer over 2500 tanks, containers and vessels for sale form our extensive stock. We provide the right solution for almost every required surface quality. The majority of our tanks have an Ra value of ≤ 0.8 µm and are therefore suitable for use in the food industry. However, we also have vessels from the pharmaceutical industry with polished or electropolished surfaces with a roughness of 0.2 - 0.5 µm. If the roughness of the inner surface is a decisive purchase criterion , we can provide a reliable measurement 0on the surface condition of a specific product via a roughness measurement through one of our partners. Our experts are happy to advise you in finding the optimal stainless steel tank with the surface roughness that suits you.

Sie möchten mehr zu dieser Leistung erfahren?

Sprechen Sie uns an.