What to Consider When Purchasing a Stainless Steel Container for Food Products

Stainless steel containers are widely used in the food industry for various purposes, such as processing milk, fruit juices, beer, or other liquid products. Due to its unique properties, such as corrosion resistance, durability, and ease of cleaning, stainless steel is the most commonly used material in container construction for the food industry. However, not every stainless steel container offers the same characteristics. There are specific requirements, especially for industrial applications in the beverage and food sectors, to ensure the highest hygiene and product safety.

In this blog post, we will highlight the key aspects to consider when purchasing a stainless steel container for food products in the industry.

1. Hygiene Standards and Surface Roughness

Hygiene requirements in the food industry are extremely high. In industrial operations that produce large quantities of liquids such as milk, fresh cheese, sauces, or beer, the containers must remain consistently clean and free from germs. Stainless steel is nearly ideal for this task. The material not only offers high corrosion resistance but is also resistant to common acids and alkalis used in cleaning processes.

Additionally, stainless steel has a non-porous surface that makes it difficult for bacteria and mold to grow. For use in the food industry, a maximum roughness (Ra) of 0.8 µm is often required. High hygiene standards apply to all parts of the container that come into contact with the product. Uneven surfaces, weld seams, or grooves could attract dirt and microorganisms, leading to poor cleaning and potential germ formation. Polished surfaces, on the other hand, minimize these risks and enable more effective cleaning. Regular inspections of the interior surfaces for cracks or corrosion damage are also essential in the food industry.

2. Avoiding Dead Spaces – A Critical Criterion for Hygiene

In industrial food containers, especially when storing and processing liquids, dead spaces (corners, edges, or indentations where liquid can remain) can be a significant issue. These areas are ideal breeding grounds for germs and bacteria and make it difficult to thoroughly clean the container.

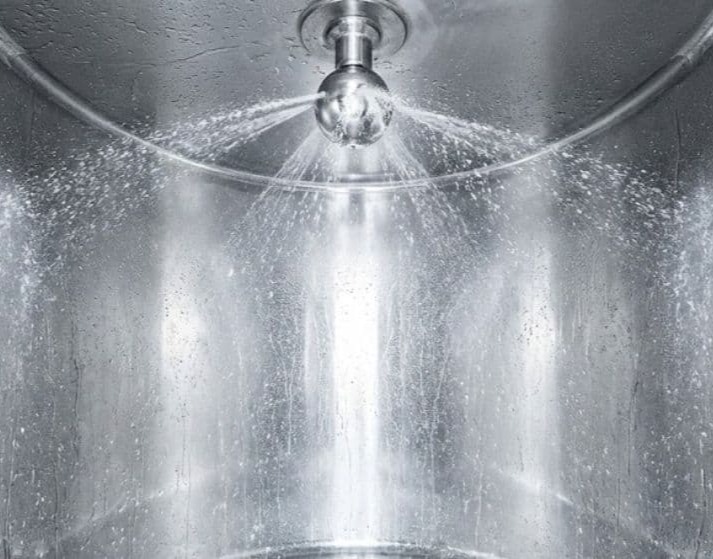

Therefore, stainless steel containers should be designed to have minimal dead spaces where liquids or food residues can settle. This is especially important for areas like manholes, outlet fittings, or pipe nozzles. When designing a stainless steel container for food, it should be ensured that all liquids can drain completely. Critical zones inside the container can be kept clean with custom-installed CIP spray balls.

3. CIP and SIP Cleaning – Efficient Cleaning Systems for Industry

Cleaning stainless steel containers in the food industry is one of the greatest challenges. In large-scale production, it is often impractical to clean the containers manually, especially when large quantities of food are processed. One solution is the so-called CIP (Clean-In-Place) cleaning, where containers can be cleaned directly on-site without being opened. Static or rotating spray heads are permanently installed inside the container via a CIP lance. The CIP process is carried out by an automated system using acid and alkali and is tailored to the exact geometry and size of the container.

In addition to CIP cleaning, a subsequent SIP (Sterilize-In-Place) cleaning can also be performed if necessary to sterilize the container. This ensures that any remaining microorganisms inside the container are killed using hot water or steam at temperatures of up to 140°C. The effect can be further enhanced by adding chemical disinfectants. The ability to perform CIP and SIP cleaning is a critical aspect when selecting a stainless steel container, as these processes are essential for maintaining high hygiene standards in continuous operations.

4. Polished Weld Seams – A Must for Germ-Free Containers

One aspect that is often overlooked but is crucial for hygiene is the weld seams inside a stainless steel container. When welding, unevenness can occur at the seams, making them hard to clean and potentially becoming a source of contamination. Polishing the weld seams removes not only cosmetic defects but also potential residues and breeding grounds for germs.

Therefore, the weld seams should be polished flat to ensure a residue-free cleaning of the product-contacting interior. Especially in the food industry, where the highest hygiene standards are required, polished weld seams have been a fundamental requirement for many years. They prevent bacteria or other microorganisms from settling in these areas and significantly facilitate cleaning.

5. Technical Requirements for Material Quality, Pressure Resistance, or Insulation

Depending on the application of the stainless steel container in the food industry, there may be additional important requirements to consider during its design. In milk processing, for example, this applies to sterile tanks, which must be designed to be pressure and vacuum resistant for the aseptic storage of food products. In milk storage, a fully welded insulation on the milk tank is crucial to maintaining the product quality by keeping the internal temperature consistently low.

In the fruit juice container sector, concentrates are often stored, which have a particularly high product density (heavier than water). The storage tanks for these must be designed to accommodate the specific density of the medium, ensuring they can safely store up to 1.37 kg per liter of product.

Some food ingredients may also have specific requirements for the material quality of stainless steel. Where conventional V2A stainless steel (e.g., 1.4301) is not sufficiently resistant, higher-quality V4A stainless steels can be used. These include materials such as 1.4401, 1.4435, or 1.4571, which offer individual characteristics like increased resistance to chlorides or consistently high temperatures.

Conclusion: The Right Stainless Steel Container is Key to Quality and Hygiene in the Food Industry

Choosing the right container is a crucial factor in ensuring high quality and hygiene standards in food production. Stainless steel provides excellent conditions due to its special properties, but the container's design must be carefully tailored to the requirements of the respective application, such as avoiding dead spaces and ensuring residue-free CIP cleaning.

Additional criteria such as polished weld seams, the correct material quality, and application-specific features like agitators, hygiene-grade insulation jackets, or pressure-resistant designs are also important factors to consider. While the initial acquisition costs may be higher due to the numerous requirements, they will pay off in the long run through improved product quality.

Good to Know:

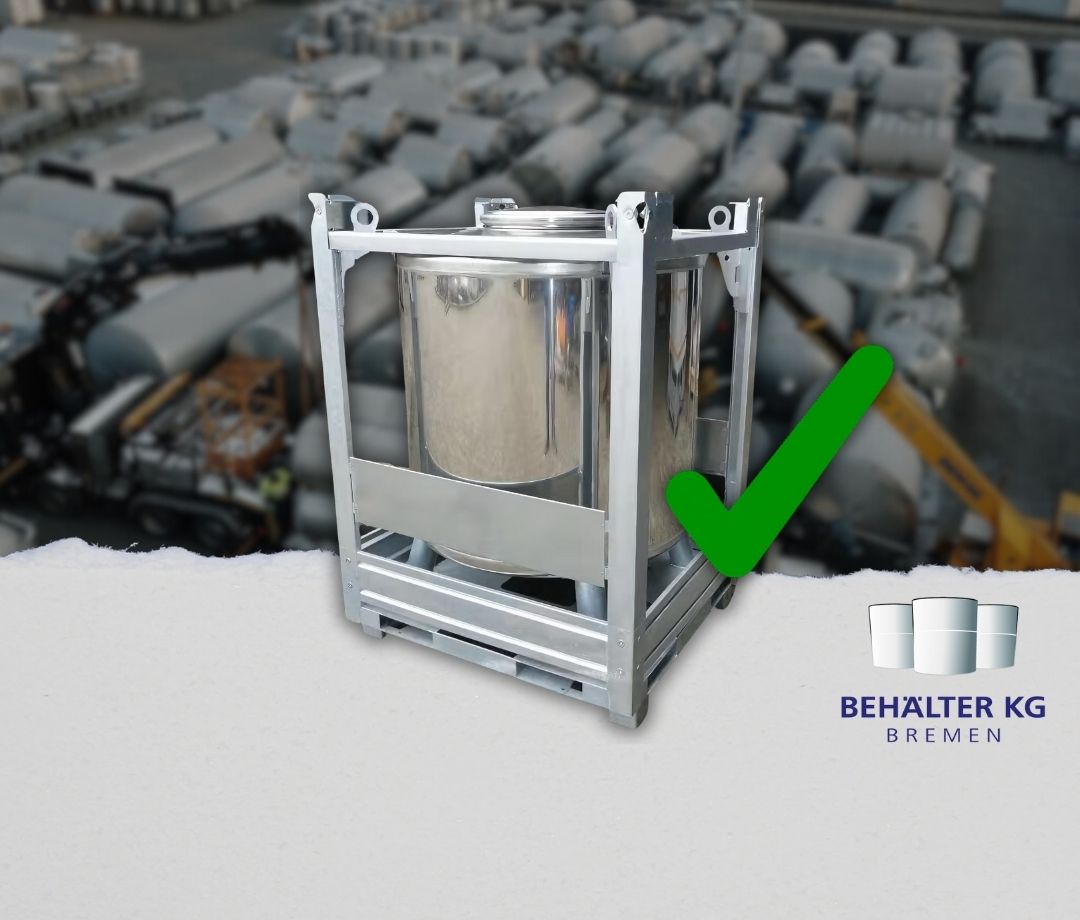

Purchasing a used food container can save time and budget without compromising on the container's requirements and quality. It also often provides the opportunity to acquire the appropriate accessories, such as CIP systems, measurement technology, and other attachments, as they were already successfully used by the previous operator.

Sie möchten mehr zu dieser Leistung erfahren?

Sprechen Sie uns an.