What Is the Viscosity of Your Product? – Table & Practical Tips for Selecting the Right Tank and Agitator

Viscosity describes the thickness (flow resistance) of liquids and gases. The higher the value, the thicker (less flowable) the medium – the lower the value, the thinner (more flowable) it is. For liquids, viscosity increases as the temperature decreases. Therefore, viscosity should always be considered together with the corresponding temperature.

For selecting the right agitator or an appropriate mixing tank, knowing the viscosity of your medium is a key factor. The viscosity table below provides practical reference values for a wide range of liquids, helping you quickly categorize your medium.

By the way: the term “viscosity” originates from the viscous juice of mistletoe berries (Viscum), which was historically used to make birdlime – so “viscous” essentially means “sticky like birdlime.”

Briefly Explained: Dynamic Viscosity (mPas)

Dynamic viscosity (η) is usually expressed in mPas (1 mPas = 1 cP). It influences, among other things, impeller geometry, motor power, seal concept, pump type, and the required heating/cooling capacity.

How to Use the Table

- Identify the medium and its temperature (adjust/convert if needed).

- Compare the viscosity range with similar media (for orientation).

- For sizing an agitator/tank: provide viscosity + temperature range + solids/particle content.

Need support? Contact us – we will recommend a suitable agitator and the right tank for your medium.

Viscosity Table (by Category)

Food & Beverages

| Medium | Temperature | (dyn.) Viscosity [mPas] |

|---|---|---|

| Apple sauce | 20 °C | 1,500 |

| Gravy | 80 °C | 110 |

| Fruit mash | 20 °C | 600 |

| Fruit juice | 20 °C | 50 |

| Fruit juice concentrate | 20 °C | 2,500 |

| Gelatin | 45 °C | 1,200 |

| Vegetable soup | 20 °C | 430 |

| Glucose | 25–30 °C | 4,300–6,800 |

| Yogurt | 40 °C | 150 |

| Condensed milk | 40 °C | 80 |

| Condensed milk, sweetened | 20 °C | 6,100 |

| Liqueurs | 20 °C | 10–100 |

| Milk | 20 °C | 2 |

| Pudding | 40 °C | 1,000 |

| Cream (30–50% fat) | 20 °C | 15–115 |

| Foam dessert | 40 °C | 1,500 |

| Processed cheese | 60 °C | 30,000 |

| Chocolate sauce | 50 °C | 280 |

| Tomato ketchup | 30 °C | 1,000 |

| Tomato paste | 20 °C | 195 |

| Sugar solution 65°Bx | 20 °C | 120 |

| Sugar solution 70°Bx | 20 °C | 400 |

Oils & Fats

| Medium | Temperature | (dyn.) Viscosity [mPas] |

|---|---|---|

| Cottonseed oil | 20 °C | 60 |

| Honey | 40 °C | 2,000 |

| Butter | 40 °C | 30,000 |

| Butterfat | 40 °C | 45 |

| Peanut oil | 40 °C | 40 |

| Cocoa butter | 60 °C | 50 |

| Bone oil | 20 °C | 300 |

| Coconut oil | 20 °C | 60 |

| Cod liver oil | 40 °C | 35 |

| Linseed oil | 40 °C | 30 |

| Corn oil | 60 °C | 30 |

| Olive oil | 40 °C | 40 |

| Oleic acid | 20 °C | 40 |

| Palm oil | 40 °C | 45 |

| Rapeseed oil | 20 °C | 160 |

| Castor oil | 20 °C | 1,000–1,500 |

| Soybean oil | 20 °C | 60 |

| Vitamin oil | 10 °C | 4,500 |

| Whale oil | 20 °C | 100 |

Chemical Products & Solutions

| Medium | Temperature | (dyn.) Viscosity [mPas] |

|---|---|---|

| Alkyd resins | 20 °C | 500–3,000 |

| Dipropylene glycol | 20 °C | 107 |

| Printing inks | 40 °C | 550–2,200 |

| Glycol | 20 °C | 40 |

| Glycerin 100% | 20 °C | 1,490 |

| Glycerin 100% | 10 °C | 4,500 |

| Glycerin 100% | 0 °C | 12,100 |

| Resin solution | 20 °C | 7,100 |

| Potassium hydroxide | 20 °C | 67 |

| Latex emulsion | 20 °C | 200 |

| Sodium hydroxide 50% | 20 °C | 45 |

| Paraffin emulsion | 20 °C | 3,000 |

| Polyester resin | 30 °C | 3,000 |

| Polymer solution | 20 °C | 20,000 |

| Polyol (A component) | 10 °C | 85,000 |

| Polyol, unpigmented | 20 °C | 500–5,000 |

| Starch solution, 25°Bé | 20 °C | 300 |

| Water-based paint | 20 °C | 900 |

Cosmetics & Pharma

| Medium | Temperature | (dyn.) Viscosity [mPas] |

|---|---|---|

| Baby food | 40 °C | 1,400 |

| Liquid egg | 45 °C | 150 |

| Liquid soap | 60 °C | 85 |

| Liquid wax | 90 °C | 500 |

| Hand cream | 20 °C | 8,000 |

| Jam | 20 °C | 8,500 |

| Mayonnaise | 20 °C | 2,000 |

| Pectin | 40 °C | 300 |

| Cleansing emulsion | 70 °C | 2,420 |

| Salad dressing | 20 °C | 1,300–2,600 |

| Toothpaste | 40 °C | 70,000 |

Lubricants & Industrial Oils

| Medium | Temperature | (dyn.) Viscosity [mPas] |

|---|---|---|

| Gear oil SAE 140 | 20 °C | 2,700 |

| Gear oil SAE 90 | 20 °C | 700 |

| Hydraulic oil HLP 100 | 20 °C | 300 |

| Hydraulic oil HLP 46 | 20 °C | 120 |

| Hydraulic oil HLP 68 | 20 °C | 195 |

| Machine oil, light | 20 °C | 150 |

| Machine oil, heavy | 20 °C | 600 |

| Engine oil SAE 5 | 20 °C | 30 |

| Engine oil SAE 10 | 20 °C | 50 |

| Engine oil SAE 15 | 20 °C | 130 |

| Engine oil SAE 15W40 | 20 °C | 390 |

| Engine oil SAE 15W40 | -15 °C | 3,000 |

| Lubricating oil | 20 °C | 60–200 |

| Transformer oil | 20 °C | 30 |

| Transformer oil | 10 °C | 75 |

| Turbine oil | 20 °C | 200–1,100 |

°Bx = °Brix | °Bé = °Baumé

(c) Bürkle GmbH 2020

Practice: Correctly Accounting for Viscosity in Tanks & Agitators

Agitator Design

- Impeller geometry: Low viscosity → propeller/axial; high viscosity → anchor agitator, Paravisc, double-frame anchor.

- Power & speed: As viscosity increases, torque rises – size motor & gearbox accordingly.

- Seals/bearings: High viscosities → robust shaft seals (e.g., double tandem with barrier fluid) and suitable bearing concepts.

Temperature Management

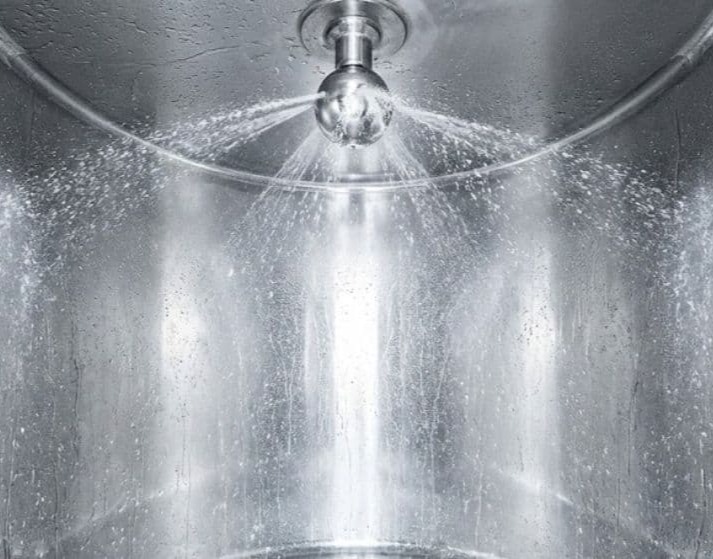

Heating/cooling jackets keep viscosity within the process window – e.g., for honey, molasses, or fats. Stable temperature lowers starting torque, shortens mixing times, and facilitates CIP cleaning.

Pumping Technology & Internal Fittings

- Pump selection: High viscosity → progressive cavity (eccentric screw) or gear pump; low viscosity → centrifugal pump often sufficient.

- Internal fittings: Baffles prevent vortex formation and improve axial flow in low-viscosity media.

Material & Surface Finish

For sticky/abrasive media, smooth stainless steel surfaces (e.g., Ra < 0.8 μm) are recommended for good discharge and hygienic cleaning. For chloride-containing media, consider stainless steel 316 grades.

Need support with the design? We will recommend the appropriate and a suitable for your medium.

Sie möchten mehr zu dieser Leistung erfahren?

Sprechen Sie uns an.