Pitting corrosion and rust: What are the causes and solutions?

Although stainless steel is commonly referred to as “rust-free,” tanks and equipment made from stainless steel are not completely immune to corrosion. Under unfavorable conditions – such as improper cleaning, contact with aggressive media, or long periods of inactivity – rust formation and pitting corrosion can occur. These damages often go unnoticed at first but can compromise the long-term functionality and lifespan of stainless steel. In this article, you will learn how pitting corrosion develops, which causes are common, and what measures can help effectively prevent corrosion.

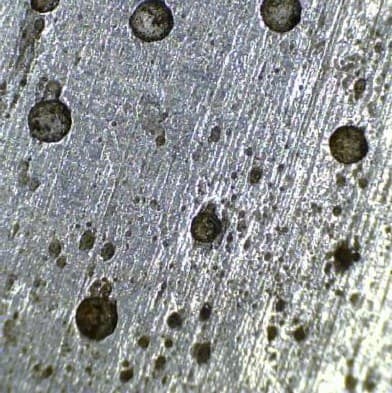

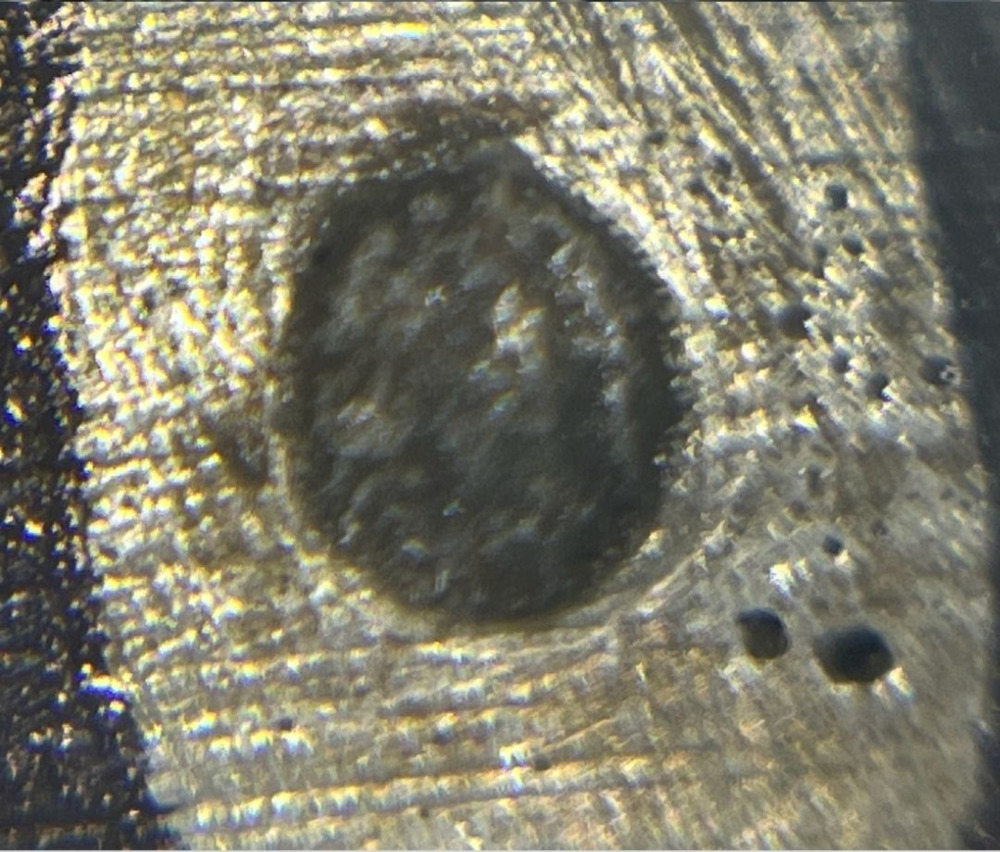

What Is Pitting Corrosion?

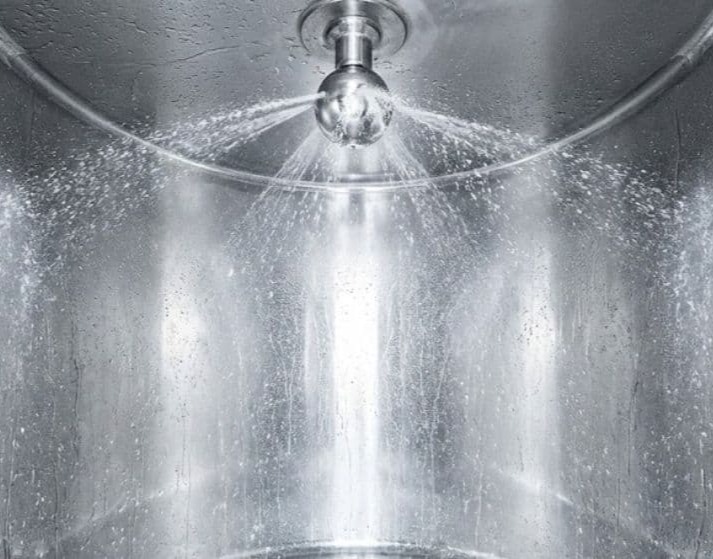

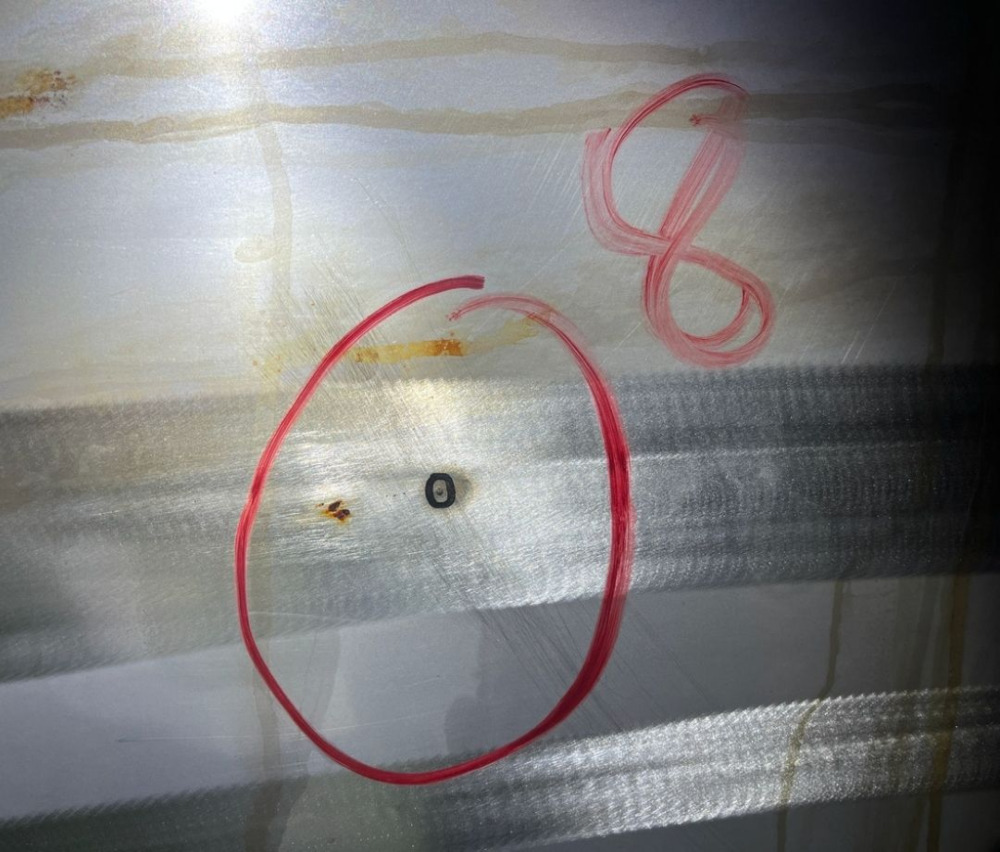

Pitting corrosion refers to small corrosion spots that can appear as pinpoint holes on the surface of stainless steel. Below the surface, the pit often expands in a funnel shape and remains unnoticed for a long time due to its minimal visibility from the outside.

The Protective Passive Layer

Every stainless steel has a passive layer – a thin oxide film that protects against rust and corrosion. This layer forms through the reaction of oxygen with the chromium content in the steel. However, external influences and contaminants can damage it.

High chloride concentrations are particularly critical – often present even in seemingly harmless media such as municipal water. Very low or very high pH values can also attack the passive layer. An analysis of your media can provide certainty. To ensure a long service life for your stainless steel tank, regular and careful cleaning is recommended.

Flash Rust in Outdoor Environments

For tanks placed outdoors, especially near railway tracks or busy roads, so-called flash rust can occur. This forms from iron particles released during braking, which are carried through the air and settle on the stainless steel surface. In combination with moisture, surface corrosion develops, visible as small rusty dots.

This type of corrosion is less critical than internal tank damage but should still be removed regularly to maintain long-term corrosion resistance.

Cleaning Light Rust Marks

Light discolorations can often be removed with simple household methods, such as a sponge and diluted cleaning solution. Afterwards, rinse the stainless steel with clean water and dry it. If this is not sufficient, a suitable chloride-free stainless steel cleaner can be used. Always follow the instructions for use, as these products should not be left on the surface for too long.

Mechanical Treatment for More Severe Damage

If rust spots remain after cleaning or material loss is already visible, the surface can be mechanically treated. Before doing so, a leak test (hydrostatic test) should be performed to assess the repair effort.

During treatment, the surface is ground until the rust marks disappear. Afterwards, pickling and passivation of the surface are recommended. Important: Tools must not have been previously used on regular carbon steel to avoid contamination with foreign particles.

Choosing the Right Material

The susceptibility of stainless steel to corrosion depends heavily on the material grade. Stainless steels commonly referred to as “V4A” (e.g. 1.4404 or 1.4571) are significantly more corrosion-resistant than the widely used “V2A” group (1.4301). The reason is a higher molybdenum content, which stabilizes the passive layer and improves resistance. Therefore, it is worth checking when purchasing a stainless steel tank whether the intended medium requires a higher-grade material.

Sie möchten mehr zu dieser Leistung erfahren?

Sprechen Sie uns an.