Tanks & Agitators Made of Stainless Steel AISI 316 (L) – Available from Stock

The materials AISI 316 and AISI 316L, also known as 1.4401 / 1.4404, are among the most common stainless steel alloys. Both materials are characterized by their increased corrosion resistance and are widely used in tank construction for the pharmaceutical, chemical, and food industries. At Behälter KG, we offer the largest selection of brand-new and used stainless steel tanks and agitators made of AISI 316 and AISI 316L in Europe. All of our products are available from stock and can be shipped worldwide. read more...

Products

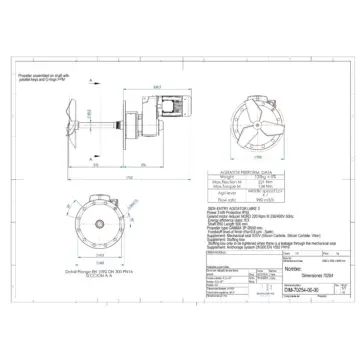

- agitator: propeller

- shaft length: 910 mm

- shaft diameter: 35 mm

- blade diameter: 200 mm

Price per piece, excl. VAT

1 on Stock

- stirrer seal: mechanical seal without thermosyphon

- agitator: propeller

- power: 3.0 KW

- output speed: 220 rpm

- shaft length: 500 mm

- shaft diameter: 50 mm

- blade diameter: 500 mm

Price per piece, excl. VAT

2 pieces on stock

- blade diameter: 1.680 mm

Price per piece, excl. VAT

1 on Stock

- agitator: blade agitator

- power: 3 KW

- output speed: 17 rpm

- shaft length: 2.620 mm

- shaft diameter: 60 mm

Price per piece, excl. VAT

2 pieces on stock

- agitator: propeller

- power: 1.3 KW

- output speed: 945 rpm

- shaft length: 500 mm

- shaft diameter: 25 mm

- blade diameter: 300 mm

Price per piece, excl. VAT

2 pieces on stock

- agitator: propeller

- power: 3.6 KW

- output speed: 1.440 rpm

- EX-proof:

- shaft length: 1.065 mm

- shaft diameter: 35 mm

- blade diameter: 190 mm

Price per piece, excl. VAT

2 pieces on stock

5,450.00 €

- max. viscosity: 20.000 mPas

- agitator: cup stirrer

- power: 2,2 KW

- output speed: 0-270 rpm

-

with 2 holes for forklift forks

- shaft diameter: 40 mm

- blade diameter: 600 mm

Price per piece, excl. VAT

2 pieces on stock

3,600.00 €

- max. viscosity: 3.000 mPas

- agitator: cup stirrer

- power: 0,75 KW

- output speed: 0-190 rpm

-

with 2 holes for forklift forks

- shaft diameter: 28 mm

- blade diameter: 600 mm

Price per piece, excl. VAT

2 pieces on stock

- max. excess pressure: 5,0 bar

- vacuum: 1,0 bar

- documents available:

- total height: 260 mm

- diameter inside: 140 mm

Price per piece, excl. VAT

70 pieces on stock

- max. excess pressure: 7,0 bar

- total height: 620 mm

- cylindrical height: 360 mm

- diameter inside: 230 mm

Price per piece, excl. VAT

1 on Stock

- max. excess pressure: 1,0 bar

- total height: 650 mm

- cylindrical height: 360 mm

- diameter inside: 230 mm

Price per piece, excl. VAT

1 on Stock

- double jacket: 3,0 bar

- insulation

- documents available:

- cylindrical height: 375 mm

- diameter inside: 406 mm

- diameter outside: 500 mm

Price per piece, excl. VAT

2 pieces on stock

- total height: 660 mm

- diameter inside: 390 mm

Price per piece, excl. VAT

1 on Stock

- total height: 760 mm

- cylindrical height: 370 mm

- total width: 460 mm

- total length: 480 mm

- diameter inside: 390 mm

Price per piece, excl. VAT

2 pieces on stock

Stainless steel 1.4401 / 1.4404 – the material for high-quality stainless steel vessels and demanding applications

Stainless steel 1.4401 and 1.4404 are among the most widely used austenitic stainless steel alloys and are indispensable in a wide range of industrial applications thanks to their excellent properties. Colloquially, they are also referred to as stainless steel 316. Both grades are renowned above all for outstanding corrosion resistance, high strength and toughness, and excellent weldability. They are used extensively in the manufacture of stainless steel vessels for demanding industries such as food, chemicals, and medical technology.

In this comprehensive article, we take a detailed look at the properties, advantages, and versatile fields of application of stainless steel 1.4401 and 1.4404, and explain why these materials are the ideal choice for stainless steel vessels. Also have a look at our article on stainless steel resistance and our overview of common materials for stainless steel vessels.

What is stainless steel 1.4401 / 1.4404?

Stainless steel 1.4401 (also known as AISI 316) and stainless steel 1.4404 are highly alloyed, austenitic stainless steels. Both grades belong to the group of stainless steels and are characterized by excellent corrosion resistance and high mechanical strength. They consist mainly of iron, chromium (16–18%), nickel (10–14%), and a special addition of molybdenum (2–3%). Molybdenum is a key factor in the exceptional corrosion resistance of these alloys because it supports the formation of a stable, passive oxide film on the surface that protects the stainless steel from aggressive chemical influences.

Key characteristics:

- High corrosion resistance: The molybdenum content provides effective protection against attack by chlorides, salts, and aggressive chemicals. This makes stainless steel 1.4401 and 1.4404 particularly suitable for vessel construction in maritime, chemical, and pharmaceutical industries.

- Austenitic structure: These alloys have high toughness and do not embrittle at low temperatures. They are also non-magnetic.

- Weldability: Both grades are readily weldable and can be integrated into complex constructions without difficulty, which predestines them for a wide variety of industrial applications.

- Hygienic properties: The smooth stainless-steel surface enables easy cleaning and prevents the accumulation of bacteria and other microorganisms. This is particularly important in areas such as food processing and medical technology.

Representation of a factory-new process vessel made of grade 1.4404

Differences between 1.4401 and 1.4404

Although stainless steels 1.4401 and 1.4404 have essentially the same chemical properties, there are some differences to consider when selecting the right grade for specific applications:

- Carbon content: The carbon content of 1.4404 is slightly lower than that of 1.4401, improving weldability and reducing the risk of cracking in the welds. For highly stressed applications or where particularly high weld seam quality is required, 1.4404 is therefore often the preferred choice.

- Corrosion resistance: Both grades offer excellent corrosion resistance; however, 1.4404, due to its lower carbon content and refined microstructure, provides even better resistance to intergranular corrosion, especially after welding.

- Mechanical properties: 1.4404 often shows higher toughness and, in many cases, strength along with better formability thanks to the lower carbon content and improved weldability. These properties make it a preferred choice in medical technology and in critical applications with high mechanical loads.

Buy used vessels & reactors in 1.4401 / 1.4404

At Behälter KG you can benefit from more than 300 stocked used process kettles, tanks, equipment, and agitators made of 1.4401 / 1.4404 (stainless steel 316). A used 1.4401/4 process vessel or storage tank is immediately available and significantly more affordable than a new purchase. This greatly reduces investment risk without compromising on material quality. By purchasing a used 1.4404 agitator or vessel you also contribute to the circular economy, since no new resources are required for production from a sustainability perspective.

For almost all equipment made of 1.4404 or 1.4401 we provide extensive technical documentation and information about the most recent application so you can quickly assess suitability for a new project. All stocked vessels and tanks can be inspected at any time at our central warehouse in Bremen.

Essential properties of stainless steel 1.4401 / 1.4404

Stainless steel 1.4401 and 1.4404 offer a variety of excellent mechanical and chemical properties that make them an ideal choice for many industrial applications:

1. Corrosion resistance

Outstanding corrosion resistance is one of the most important features of stainless steel 1.4401 and 1.4404. Thanks to the molybdenum content, these stainless steels provide excellent protection against:

- Chlorides (salts), found especially in maritime environments or in the food industry

- Acids, including many organic and inorganic acids

- Alkalis and other chemically aggressive substances

- High-temperature corrosion, particularly in environments with fluctuating thermal loads

This exceptional corrosion resistance is a decisive reason why vessels made of 1.4401 and 1.4404 are used in numerous demanding applications.

2. Strength and toughness

Stainless steels 1.4401 and 1.4404 are characterized by high strength and toughness. They retain structural integrity even at low temperatures and are highly resistant to mechanical loads. This makes them ideal for applications where both mechanical and thermal stresses may occur.

3. Heat resistance

Although stainless steel 1.4401 and 1.4404 are not intended for continuous use at extremely high temperatures (above 400 °C), they still offer very good resistance to short-term overheating and temperature fluctuations. This makes them an excellent choice for applications in hot environments such as food processing or chemical plants.

4. Weldability and formability

Both grades are excellently weldable, even at thin wall thicknesses. The weldability of 1.4404 is even better due to its lower carbon content. Stainless steel 1.4401 and 1.4404 can be integrated into complex structures and vessel designs without the risk of cracking or corrosion at the welds.

5. Hygiene and cleanliness

Another outstanding characteristic of stainless steel 1.4401 and 1.4404 is the high level of hygiene and ease of cleaning of the surface. This is particularly important in the food industry, medical technology, and the pharmaceutical sector. The smooth, pore-free surface prevents the accumulation of bacteria and other microorganisms — crucial for food safety and compliance with hygiene regulations.

Applications of stainless steel 1.4401 / 1.4404

Stainless steel 1.4401 and 1.4404 are used across a wide range of industries. Particularly notable are:

1. Food industry

In the food industry, vessels made of 1.4401 and 1.4404 are of critical importance. They are used in numerous applications, e.g., for storage, transport, and processing of foodstuffs. Resistance to salts, acids, and alkalis, together with hygienic properties, makes these grades ideal for the production of storage tanks, kettles, silos, mixing tanks, and other vessels.

2. Chemical industry

The chemical industry requires materials capable of withstanding attack by aggressive chemicals. Stainless steel 1.4401 and 1.4404 are the preferred choice for manufacturing pipelines, reactors, storage tanks, and pressure vessels that come into contact with acids, alkalis, and other aggressive substances.

3. Medical technology and pharmaceutical industry

Vessels made of 1.4401 and 1.4404 are indispensable in medical technology due to their excellent hygienic properties and corrosion resistance. They are used to manufacture medical devices and instruments, as well as for the storage of pharmaceutical substances and chemicals. Excellent cleanability and the ability to maintain sterility are crucial here.

4. Water and wastewater treatment

Water treatment and wastewater processing impose special requirements on material resistance. Stainless steels 1.4401 and 1.4404 are resistant to corrosion caused by aggressive substances that can occur in wastewater. Vessels made of these alloys are therefore frequently used for storing and transporting water, chemicals, and other liquids in water and wastewater treatment.