Sterile tanks for aseptic storage: properties and special features

The aseptic storage of liquids plays a crucial role in many industries, especially in the food, beverage and pharmaceutical industries. Sterile tanks are used for this purpose, in which sensitive products, such as milk, can be stored before aseptic filling. In this article, we would like to summarise the most important features of a sterile tank and show why these tanks are indispensable for aseptic storage.

What is a sterile tank?

A sterile tank, often also called an aseptic tank, is a tank specifically designed for the sterile storage of liquids that are particularly sensitive to contamination. The task of a sterile tank is to protect the product from microbial contamination while maintaining product quality over an extended period. Sterile tanks are used primarily in production processes where the highest hygiene and safety standards are required. For this purpose, sterile tanks are usually operated under overpressure, with the product space supplied with sterile air or inert gas.

Special features of a sterile tank

Sterile tanks differ from conventional tanks through several specific features:

- Sterile atmosphere control: To ensure aseptic storage, a controlled sterile atmosphere is often maintained in the sterile tank. This is achieved by introducing sterile gases (e.g., nitrogen) that prevent oxygen ingress and thus the proliferation of microorganisms.

- Hermetic sealing: One of the most important characteristics of a sterile tank is its hermetic sealing. This means that, thanks to the application of overpressure in the product space, neither air nor other particles from outside can enter the tank. This minimizes the risk of contamination by bacteria, germs, or other microorganisms.

- Materials and surface finish: Sterile tanks are generally made of stainless steel, often of particularly corrosion-resistant grades such as 1.4404 or 1.4571 (“stainless steel 316”). The weld seams in the product space are ground to create the smoothest possible surface. The roughness of product-contact surfaces is Ra ≤ 0.8 µm, with even stricter requirements in the pharmaceutical sector (e.g., electropolished surfaces). The resulting hygienic design ensures that as few bacteria or product residues as possible can adhere inside.

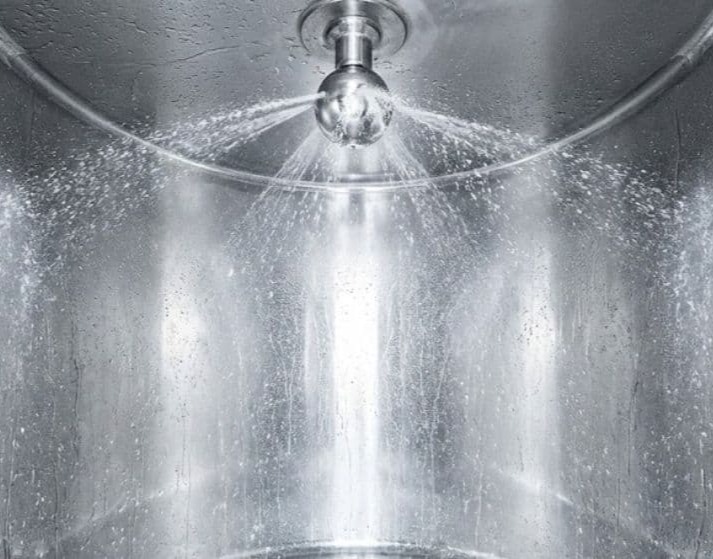

- Integrated sterilization systems: Another advantage of sterile tanks is the possibility of CIP (Cleaning-in-Place) and SIP (Sterilization-in-Place). These systems allow the tank to be cleaned and sterilized after each use without opening it. Sterilization and cleaning are usually fully automatic, making the production process more efficient and safer. Sterilizing the product interior with steam, e.g., at 120 °C, makes it absolutely necessary for the sterile vessel to be designed for slight vacuum as well.

- Operating pressure and temperature: Sterile tanks are engineered to meet specific pressure and temperature requirements. Typically, a sterile tank is rated for an operating overpressure of +3.0 bar and full vacuum (−1.0 bar operating underpressure). The operating temperature range spans below 0 °C up to 150 °C to enable aseptic storage as well as regular steam sterilization. An external cooling jacket ensures efficient cooling of the product space by circulating chilled water through the coil of the double jacket.

- Sterile valves and fittings: To discharge the tank contents aseptically, sterile tanks feature special sterile valves and fittings that ensure a hygienic transfer of liquids. These connections are designed to prevent cross-contamination by particles or microorganisms from outside.

Advantages of aseptic storage in sterile tanks

- Maintained product quality: Sterile tanks protect sensitive liquids from contamination and help preserve quality over longer periods.

- Extended shelf life: Thanks to sterile storage, the product remains stable for longer, which is crucial for the storage and transport of perishable goods.

- Safe process: Automated cleaning systems and sterile connections minimize the risk of human error and thus the risk of contamination.

Applications of sterile tanks

Sterile tanks are used in various industries, especially where hygiene and product safety have top priority:

- Food and beverage industry: Sterile tanks are used particularly in the production of dairy products, fruit juices, or baby food.

- Pharmaceutical industry: In the manufacture of vaccines, medicines, and other biotechnological products, sterile storage is critical.

- Cosmetics industry: For special lotions, serums, or sterile solutions, sterile tanks play an important role in preventing contamination.

Can sterile tanks also be purchased used?

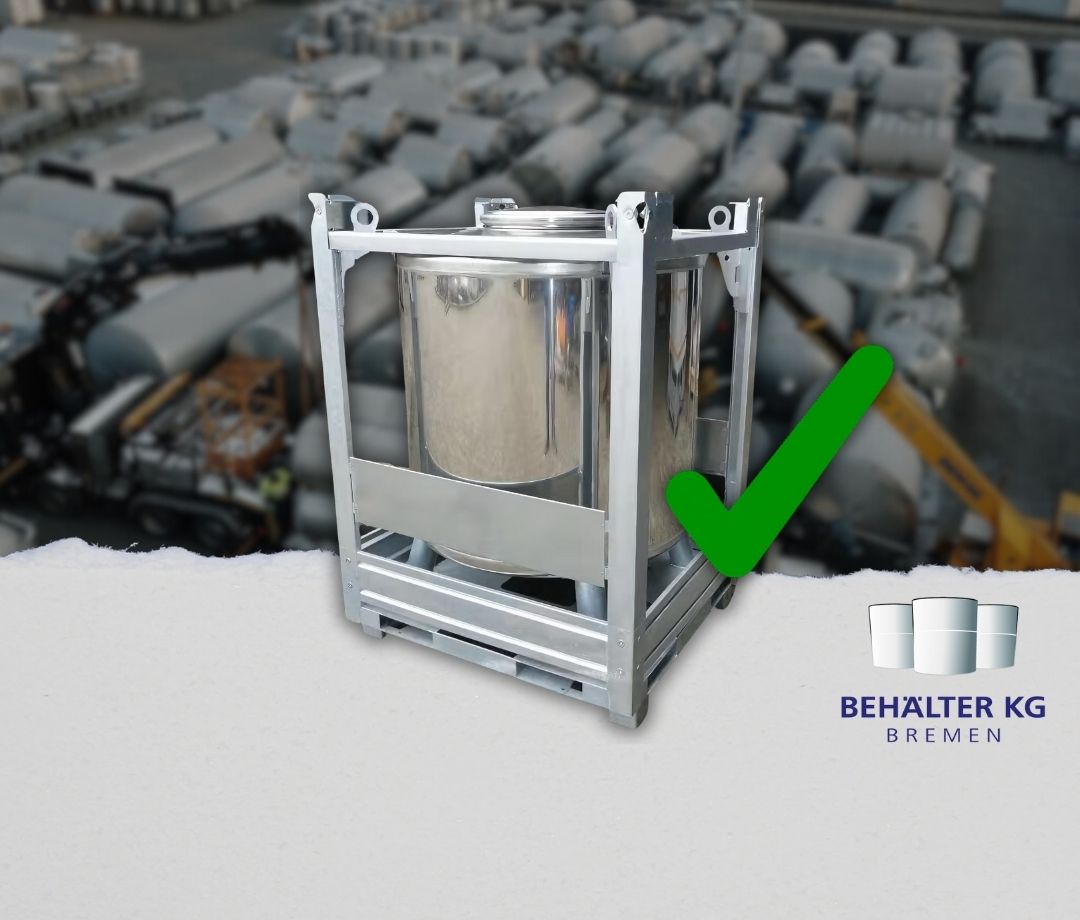

Behälter KG consistently carries a broad range of used sterile tanks, from small 500-liter sterile vessels to sterile tanks with capacities of up to 40,000 liters. Used sterile tanks often come from renowned large dairies or food corporations, where they are decommissioned due to production relocations or shutdowns. Used sterile tanks and aseptic vessels are available immediately and do not require long lead times. They are also significantly more affordable than comparable new purchases, keeping investment risks low. Many used sterile tanks are equipped with high-quality sterile fittings, magnetic agitators, and other practical features. The documentation that is usually available allows the usage history to be traced. Upon request, we can also offer crack testing of the product interior for all our used sterile tanks. Before deciding to purchase a used sterile vessel, you can personally verify the quality of our products at our central warehouse in Bremen.

(Sample image of a used sterile tank)

Conclusion

Sterile tanks are indispensable for the production and filling of various foods, beverages, or pharmaceuticals. By supplying the product space with sterile gases, storing under constant overpressure, and using sophisticated cleaning and sterilization cycles, products with the highest hygiene requirements can be processed safely and without contamination. As an alternative to factory-new sterile tanks, you can also draw on a wide selection of used sterile tanks, which involve a comparatively low investment and short delivery times.

Sie möchten mehr zu dieser Leistung erfahren?

Sprechen Sie uns an.