Briefly explained: What is CIP cleaning?

CIP cleaning (Cleaning in Place) is the automated internal cleaning of tanks, pipelines, and process systems in their installed state – without dismantling product-contact components.

- Purpose: Reproducible cleaning of closed systems in process and production environments.

- Benefits: Standardized results, reduced dismantling effort, and documented process control.

- Process: Pre-rinse → main cleaning → intermediate/final rinsing → optional acidic cleaning → final rinse → optional disinfection/drying.

Distinction: CIP cleans within the system. COP (Cleaning out of Place) requires dismantling and external cleaning of individual components.

When is CIP cleaning useful?

CIP is useful when product-contact internal surfaces must be cleaned regularly and dismantling would unnecessarily prolong or complicate operation.

Typical applications include recurring cleaning cycles in closed systems where cleanability, downtime, and process reliability are key factors. Whether CIP is the appropriate solution depends, among other things, on product residues, geometry, internals, hygiene requirements, and cleaning verification.

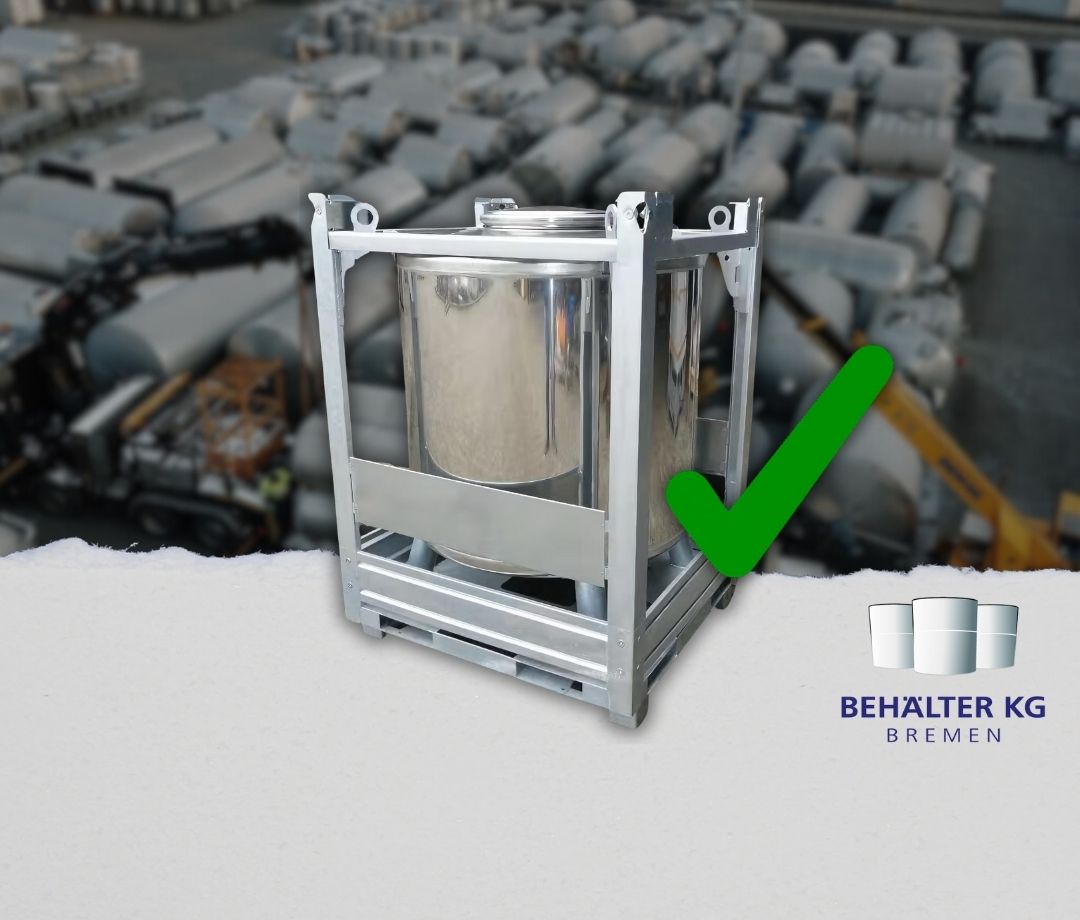

- Process and storage tanks: Internal cleaning of stainless steel vessels with permanently installed internals.

- Pipelines and valve manifolds: Cleaning hard-to- reach areas without opening the system.

- Heat exchangers: Removal of deposits depending on medium, temperature, and type of fouling.

What is the difference between CIP and COP?

The key difference is that CIP cleans within a closed system, whereas COP requires dismantling and external cleaning of individual components.

In practice, CIP and COP are not considered opposites but complementary cleaning strategies. Certain components may still require partial dismantling despite CIP, for example when geometry, sealing areas, or deposits limit reliable in-system cleaning.

- CIP: Automated in-system cleaning, suitable for recurring cycles and standardization.

- COP: Cleaning outside the system, suitable for components that require targeted inspection or manual treatment.

- Combination: CIP for the system plus COP for defined assemblies (process- and risk-based).

Which industries and processes typically use CIP?

CIP is used across industries wherever process systems must be cleaned regularly and defined hygiene standards must be met.

CIP is established in many industries as soon as products, residues, or quality requirements make standardized cleaning necessary. Specific parameters and verification depend on the medium, plant design, and quality specifications.

- Food & Beverage: Product changes, hygiene, and reproducible cleaning in tanks and pipelines.

- Pharma/Biotech: Documentation- and verification- driven cleaning, often with formal release procedures.

- Chemicals/Fine chemicals: Material- and resistance-driven design depending on media and residues.

- Cosmetics/Personal Care: Cleanability for viscous products and sensitive formulations.

What technical requirements must a system meet for CIP?

A system is only CIP-capable if all product-contact areas can be fully wetted and no relevant residues can permanently adhere.

CIP capability is primarily a matter of design and installation. Key factors include flow paths, avoidance of dead legs, suitable connections, and geometry that allows cleaning under real flow conditions.

- Hygienic design: Constructive design for cleanability and avoidance of deposit zones.

- Avoidance of dead legs: No blind ends, short branch lines, suitable valve technology, defined slopes.

- Wettability: Spray technology, internals, and positioning must reliably reach internal surfaces.

- Drainability: Residual drainage and drip behavior influence cleaning effort and repeatability.

What role do materials, surfaces, and seals play in CIP?

Material selection, surface condition, and sealing systems determine how resistant and cleanable product-contact areas remain during CIP operation.

For stainless steel vessels and process components, corrosion resistance, surface quality, and the chemical and thermal resistance of seals are relevant. Requirements result from the product, cleaning media, temperature profile, and cleaning frequency.

- Stainless steel materials: Common grades include 1.4301, 1.4404, or 1.4571 (selection depends on medium and cleaning chemistry).

- Surfaces and welds: Smooth, accessible surfaces and properly executed welds reduce the risk of deposits.

- Seals: Materials such as EPDM, FKM, or PTFE are selected depending on chemical and temperature resistance.

- Material compatibility: Media and cleaning chemistry must be considered together to avoid corrosion or swelling.

How does a CIP process work step by step?

A CIP process consists of defined stages that successively dissolve, remove residues, and establish the condition for release.

The specific sequence is adapted to product, fouling, system, and verification requirements. The order of steps is important to avoid fixing residues and to use cleaning chemicals effectively.

- 1) Pre-rinse: Removal of coarse residues and preparation of internal surfaces.

- 2) Alkaline main cleaning: Removal of organic fouling such as fats or proteins (depending on product and chemistry).

- 3) Intermediate/final rinse: Removal of cleaning chemicals and transition to the next stage.

- 4) Acidic cleaning (optional): Removal of mineral deposits depending on medium and water quality.

- 5) Final rinse: Rinsing to a defined condition based on measurement and release criteria.

- 6) Disinfection or thermal treatment (process-dependent): Optional depending on hygiene and safety requirements.

- 7) Draining/drip-off/drying: Relevant for sensitive product changes or moisture requirements.

Which mechanical factors are decisive in CIP?

Cleaning success is not achieved by chemistry and temperature alone, but largely by wetting, flow, and mechanical action.

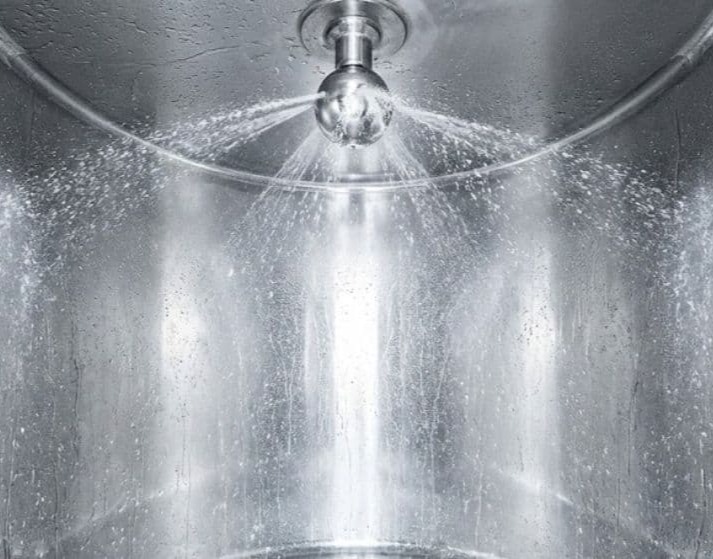

In vessels, mechanical action is often generated by spray devices and flow conditions. In pipelines and distributors, flow guidance is critical for detaching and removing deposits. Internals such as agitators or heat exchangers significantly influence cleanability.

- Spray technology: Selection and positioning (e.g. spray ball or rotary spray head) depending on geometry and requirements.

- Flow: Pipeline cleaning requires suitable flow conditions to detach deposits.

- Internals: Agitators, baffles, sensors, or heating/ cooling surfaces can create shadow areas.

- Heat exchangers: Tendency to foul depends on medium and temperature and requires specific attention.

How is CIP monitored and documented?

CIP processes are monitored via measured values and logs to demonstrate reproducible conditions.

In practice, process parameters are recorded, monitored, and documented. Which variables are required depends on the industry, internal quality specifications, and the expected level of verification.

- Temperature: Monitoring cleaning effectiveness and process safety.

- Conductivity or concentration indicators: Detection of media changes and rinse states.

- Flow/pressure: Plausibility check of flow conditions and spray effectiveness.

- Time/program control: Ensuring the defined sequence of steps and minimum times.

How is cleaning effectiveness verified?

Cleaning verification is carried out using suitable test methods and distinguishes between one-time verification (validation) and ongoing control (verification).

Required verification depends on risk, product, hygiene requirements, and internal release processes. In many cases, multiple methods are combined to cover both residue and microbiological aspects.

- Visual inspection: Basic check, but not sufficient for all applications.

- Swab tests: Detection of residues at defined sampling points.

- ATP tests: Rapid indicator for organic contamination (interpretation- and environment-dependent).

- Microbiological analyses: Relevant for hygienic safety depending on industry.

- Wetting tests: Verification that critical surfaces are reliably reached (e.g. dye/riboflavin methods, method-dependent).

Which typical errors cause problems despite CIP?

Many CIP issues arise from design weaknesses, unsuitable parameters, or insufficient monitoring.

When residues occur repeatedly, the cause is often not a single parameter but a combination of geometry, wetting, media routing, and operating conditions. A structured root-cause analysis starts at the system’s critical areas.

- Dead legs and blind ends: Retention areas lead to recurring contamination.

- Shadow zones caused by internals: Spray patterns do not reach all surfaces.

- Unclear rinse criteria: Media changes without reliable indication increase the risk of chemical residues.

- Material/seal issues: Swelling, aging, or corrosion affect cleanability and tightness.

- Insufficient draining: Residual volumes increase carryover and contamination risks depending on the process environment.

Which configuration options are typically relevant for CIP-capable vessels?

CIP capability is shaped by connections, internals, and instrumentation that may enable or hinder complete cleaning.

Even without selecting a specific product, typical configuration areas can be identified that should be reviewed during design, retrofit, or assessment of a system. Relevance depends on product, process, and verification requirements.

- Interfaces/connections: CIP supply, return, drainage, venting, sampling (each designed to be dead-leg-free).

- Spray devices: Static spray ball or rotary spray heads, positioning depending on geometry.

- Agitator/internals: Cleanability of shafts, seals, baffles, internals, and sensors.

- Double jacket/heating-cooling surfaces: Influence on temperature control and process stability (application- dependent).

- Insulation/environment: Relevance for heat losses and condensate (process-dependent).

- Instrumentation: Temperature, conductivity, flow, pressure, and optional process analytics (requirement- driven).

Which questions must be clarified before implementing a CIP process?

For a robust CIP decision, product, geometry, verification requirements, and operating procedures must be considered together.

- Product and residues: What contamination is expected (organic/mineral, viscous, adhesive)?

- Geometry: Are there dead legs, blind ends, unfavorable installation positions, or hard-to-wet internals?

- Verification level: Which internal release criteria apply (QS/QA) and how are they tested?

- Parameter control: Which media, temperatures, and times are fundamentally permissible (material- and process- related)?

- Monitoring: Which measured values are recorded and how is media change clearly detected?

- Operation: How frequent are product changes, and how critical are downtime and cleaning duration?

- Maintenance: Which seals and wear parts are affected and how is their condition monitored?