Inspection & approval of used IBC containers – what you need to know

Used IBCs (Intermediate Bulk Containers) are used in many industries for the storage and transport of liquids or bulk materials, often also for hazardous substances. To ensure that these reusable vessels can continue to be used safely and in compliance with regulations, they must be inspected and re-approved at regular intervals. In this blog post, you will learn which regulations apply, which inspection intervals must be observed, and what to look out for when inspecting and approving used IBC containers. We will also introduce you to an experienced partner who can support you with the inspection of your IBCs.

Why used IBCs must be inspected

Every IBC used for hazardous materials is subject to the ADR regulations (European Agreement concerning the International Carriage of Dangerous Goods by Road). This specifically means that the following inspections are legally required:

- Every 2.5 years: Intermediate inspection (visual and functional check)

- Every 5 years: Full inspection by an approved inspection body

- Additionally: Inspection after repairs or in case of damage

These inspection intervals apply to all common IBC types – both stainless steel IBCs and plastic IBCs. Once the deadlines have passed, an IBC may no longer be filled or transported until the corresponding inspection has been successfully carried out.

Which documents are required for the inspection – and which are not

As a dealer for used IBC containers, we know that many customers are unsure about this question: “Do I need old inspection reports or technical documents for approval?”

The answer: No. If old reports or technical documents are missing, the IBC can still be inspected and approved. What matters is that it is identifiable – for example, via the nameplate with UN approval number, manufacturer, and year of manufacture.

Also important is the type drawing. It shows how the IBC was originally constructed and serves as a reference during inspection. If it is not available, it can be requested from the manufacturer or the approved inspection body – a service often provided by the service provider for its customers.

How an IBC inspection works

A proper IBC inspection includes several steps:

- 1. Visual inspection – checking for deformations, cracks, corrosion, or other damage

- 2. Wall thickness measurement – especially for metal IBCs, to detect material loss

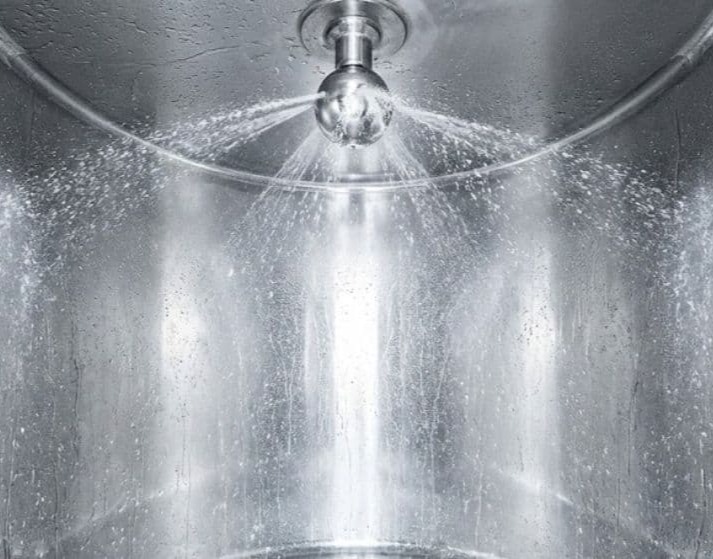

- 3. Leak test – vessel is tested under slight overpressure

- 4. Inspection of fittings – valves, lids, and outlets are checked

- 5. Replacement of seals – often as a precaution to avoid leaks

- 6. Function test – ensuring all parts are operable

If the IBC passes the inspection, it receives a new inspection marking on the nameplate and a current inspection report.

Cost-effectiveness: buying used instead of new

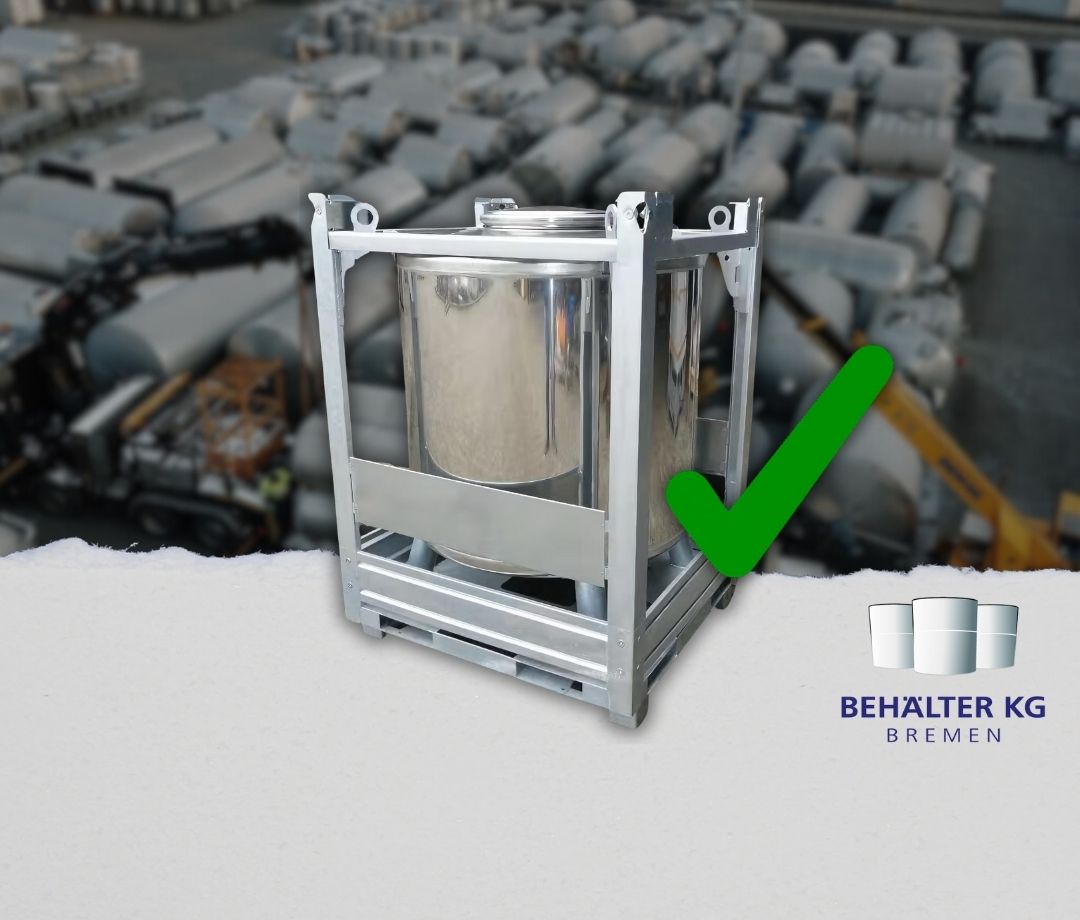

Re-approval of used IBCs is in many cases significantly cheaper than purchasing a comparable new one. In addition to cost, fast availability and the sustainability aspect also play a major role: each reused IBC saves resources and CO₂!

Support from experienced inspection bodies

Many approved inspection bodies offer additional services besides the actual inspection, such as cleaning, repairs, and procurement of missing type drawings.

As a long-standing partner of Behälter KG, we recommend that our customers entrust the specialist company Contek IBC Service with the inspection and approval of IBC containers. As an approved inspection body, Contek offers inspections both at the plant and on your premises. In addition, accompanying services such as IBC cleaning or the installation of spare parts can also be offered by Contek easily and reliably from a single source.

Sie möchten mehr zu dieser Leistung erfahren?

Sprechen Sie uns an.