ATEX approval for agitator vessels

In many industries such as chemicals, pharmaceuticals, or food processing, mixing tanks are indispensable. However, when handling flammable liquids or gases, special safety standards must be observed. ATEX approval ensures that equipment such as agitators and stainless steel vessels can be operated reliably and safely even in potentially explosive areas. In this article, you will learn what ATEX certification means, which EX zones exist, and what to consider when selecting mixing tanks.

What does ATEX approval mean?

ATEX stands for “Atmosphères Explosibles” and is based on the EU directives 2014/34/EU (Product Directive, manufacturer obligations) and 1999/92/EC (Operation Directive, operator obligations). They define the requirements for equipment and protective systems used in potentially explosive atmospheres to protect people, facilities, and the environment.

Key basics

- 2014/34/EU (Product Directive): defines the obligations manufacturers must meet when designing and assessing the conformity of equipment and protective systems.

- 1999/92/EC (Operation Directive): regulates operator obligations, i.e., how companies must set up and operate workplaces in EX zones safely.

- Risk assessment: forms the basis of every decision – the operator evaluates whether an explosive atmosphere may occur at the place of use and which protective measures are required.

Conformity is documented by CE/Ex marking, type of explosion protection (e.g., Ex d, Ex e), and temperature class (T1–T6). These specifications must match the medium, process conditions, and zone.

Which EX zones exist?

Potentially explosive areas are classified into zones depending on the frequency and duration of explosive atmospheres:

- Zone 0: High probability – explosive atmosphere is present constantly or frequently, typically inside tanks/vessels with flammable liquids or gases.

- Zone 1: Medium probability – explosive atmosphere occurs occasionally, e.g., at vents, filling points, or process outlets.

- Zone 2: Low probability – explosive atmosphere occurs rarely and only for short periods, e.g., near pipelines or safety valves.

Equipment categories & marking

- Category 1G: for Zone 0 – very high level of protection.

- Category 2G: for Zone 1 – high level of protection.

- Category 3G: for Zone 2 – normal level of protection.

Example marking: II 2G Ex IIB T4 Gb (Equipment group II, Category 2G, Gas group IIB, Temperature class T4).

Practical example: Agitator in a stainless steel vessel

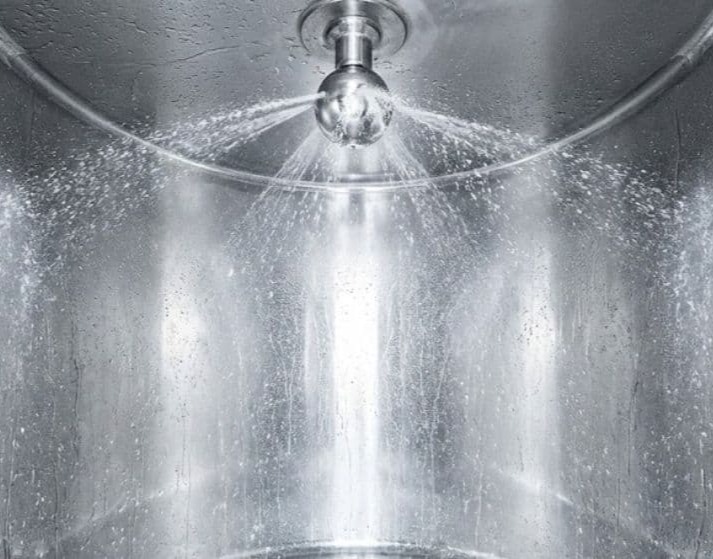

In the chemical industry as well as in food, beverage, and pharmaceutical production, agitators are often used in stainless steel mixing tanks. Stainless steel is corrosion-resistant, hygienic, and easy to clean – ideal for sensitive processes.

In EX areas, all installed components – agitator, motor/drive, seals, measuring and safety technology – must be in explosion-proof design. The product chamber is often classified as Zone 0, while the external area is Zone 1 or 2.

Depending on the application, an agitator can also be operated in Zone 1, for example, when volatile vapors or gases occasionally occur in the surroundings. The exact classification depends on the medium, viscosity, temperature, and operating conditions.

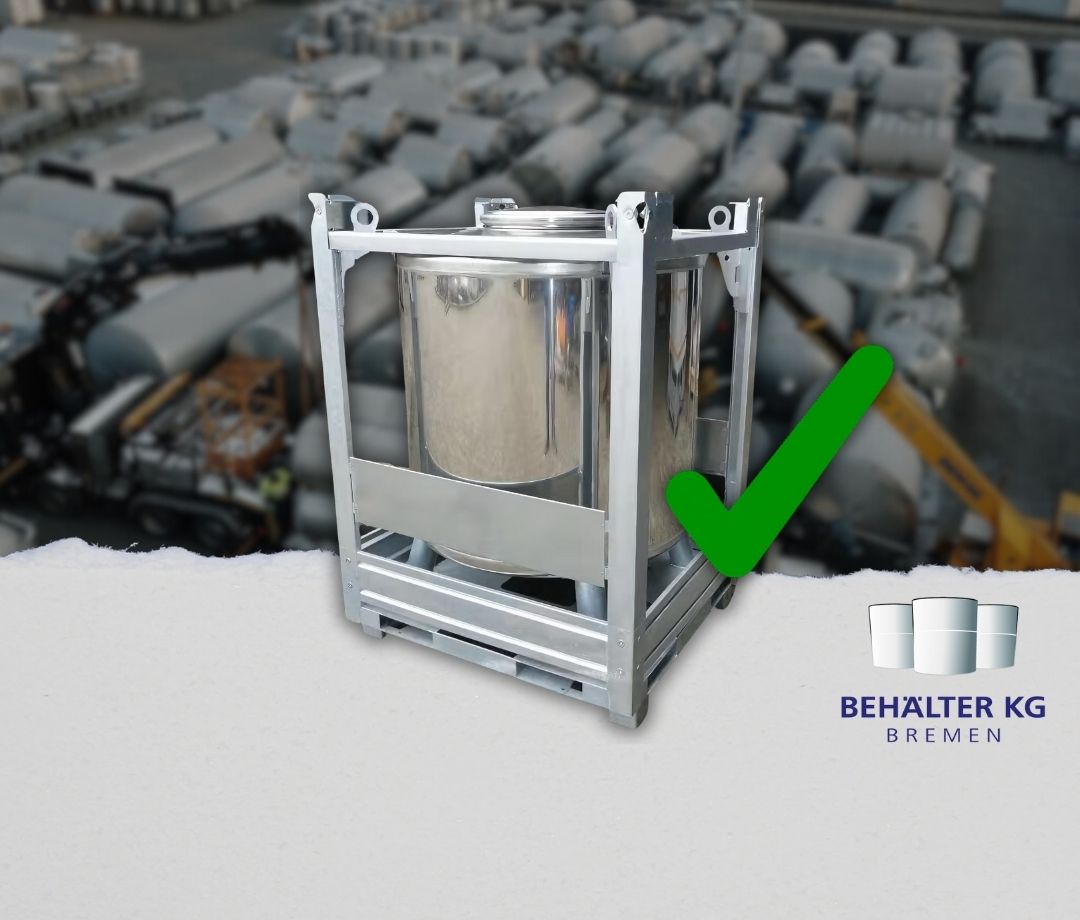

Used EX vessels: Used mixing tanks in explosion-proof design are also suitable, provided that their condition, documentation, and marking comply with current ATEX requirements. Since standards are regularly updated, possible retrofitting or adjustments should be considered.

Browse directly: Mixing tanks in stock

Tips for selection & operation

- Determine the zone: Operator’s risk assessment forms the basis.

- Check components: Agitator, motor/gearbox, seals, sensors, and grounding must be ATEX-compliant.

- Grounding/equipotential bonding: avoid electrostatic charging and ignition sources.

- Medium & temperature class: choose the appropriate temperature class in relation to the flash point.

- Documentation: CE/Ex marking, declaration of conformity, operating manual must be available.

- Used equipment: Have condition and documentation checked by a specialist; plan retrofitting if necessary.

FAQ: ATEX approval, EX zones & explosion-proof stainless steel mixing tanks

Sie möchten mehr zu dieser Leistung erfahren?

Sprechen Sie uns an.