Tecnologías de calefacción y refrigeración para tanques y reactores de acero inoxidable

Muchas operaciones de ingeniería de procesos y flujos de producción requieren un control térmico fiable de los tanques de acero inoxidable. Ya sea calentamiento o refrigeración, la gestión precisa de la temperatura es crucial para la calidad y la eficiencia. Especialmente en reactores, tanques de fusión o tanques de almacenamiento, el intercambio térmico forma parte esencial de su función.

A continuación presentamos los diseños técnicos más comunes para circuitos de calefacción y refrigeración —desde serpentines de media caña hasta calentamiento eléctrico— junto con sus ventajas y áreas típicas de aplicación.

Half-Pipe Coil

The half-pipe coil consists of semi-circular pipe segments welded in tight windings around the outer wall of the tank. It is suitable for both liquid and vapor media and, depending on the design, can withstand extreme temperatures and pressure levels. It is often used in the chemical and pharmaceutical industries, for example, for continuous temperature control with thermal oil, saturated steam, or hot water.

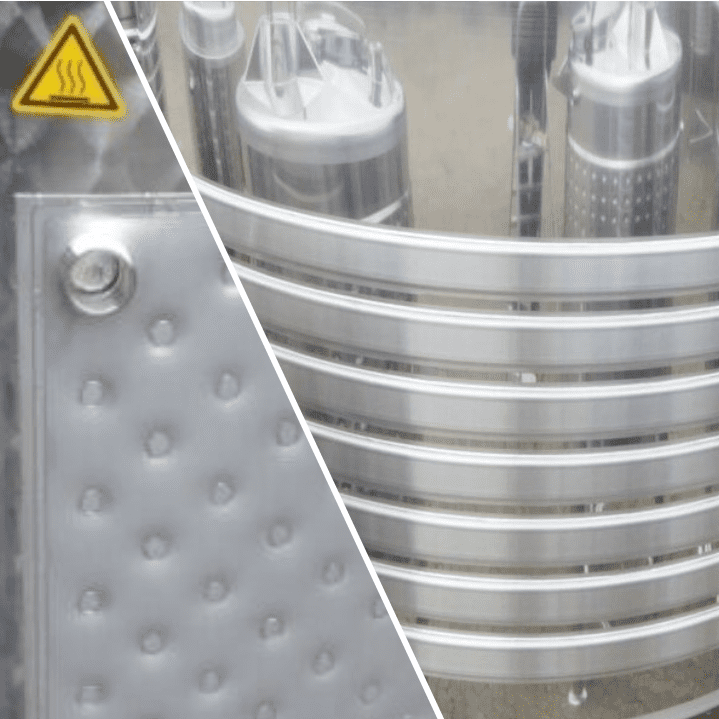

Thermoplate / Pillow Plate

In the Thermoplate technique, a thin stainless steel sheet is welded onto the tank shell, and the cavity is then inflated using high pressure. The result is a convex structure with an optimal heat transfer surface. Unlike the half-pipe coil, there are no untempered gaps, which increases efficiency. Pillow Plate is the common technical term, while Thermoplate is the registered brand name.

A variation is the so-called Dimple Plate, where the sheet is pre-pressed, resulting in a different appearance and lower pressure resistance – but sufficient for liquid media.

Full-Pipe Coil

The full-pipe coil is usually mounted inside the tank, coming into direct contact with the medium. It is pressure-resistant, cost-effective to retrofit, and easy to repair. Disadvantages include possible dead zones during cleaning and the risk of contamination in case of leakage.

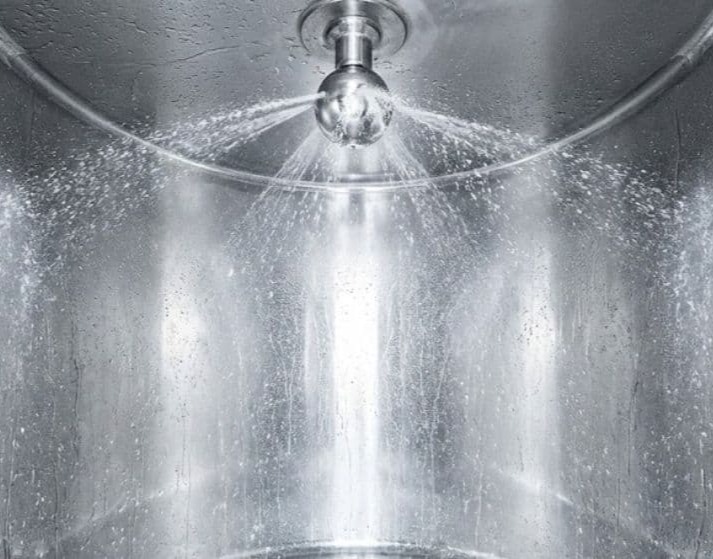

Jacketed Shell

A jacketed shell encloses the tank shell or only the bottom section with a second layer. This is filled with heating or cooling medium and, due to its large exchange surface, offers very good temperature transfer. Disadvantages include the high volume of tempering fluid required and lower pressure resistance. In the dairy industry, the jacketed shell is often used without pressure in combination with a spray ring for ice water.

Immersion Heaters / Tube Bundles

Immersion heaters or tube bundles are inserted from the side into the tank. They can be electrically operated or tempered with circulating thermal oil or hot water. Advantage: easy retrofitting. Disadvantage: cleaning inside the tank is more difficult.

Electric Heating with Heating Cable / Heating Jacket

In this method, the tank is wrapped with heating cables or heating jackets. This approach is suitable for frost protection, temperature maintenance, and also for high-temperature applications of over 300°C. However, it is energy-intensive and therefore more suitable for smaller batches.

Electric Heating Indirectly via Heat Transfer Fluid

This method combines a jacketed shell with integrated electric heating rods. The shell is filled with thermal oil, which is heated and transfers its heat to the product chamber.

Looking for a heatable or coolable tank? Contact us by phone or email at mail@behaelter-kg.de for individual advice.

¿Desea obtener más información sobre este servicio?

Póngase en contacto con nosotros.