6 errores comunes al operar un tanque de acero inoxidable

Los recipientes de acero inoxidable son indispensables en muchos sectores industriales: alimentario, químico o farmacéutico. Son robustos, duraderos y de bajo mantenimiento. Sin embargo, incluso pequeños errores operativos pueden acortar significativamente su vida útil e incluso provocar daños costosos. En este artículo presentamos los seis errores más comunes al manejar tanques de acero inoxidable y cómo evitarlos fácilmente.

1. Choose the right stainless steel grade

Check whether your medium requires a higher-grade material. The most widely used material group for stainless steel vessels is stainless steel 304 (1.4301, AISI 304). However, there are numerous alloys that, through additives such as molybdenum, offer greater corrosion or temperature resistance. These are often grouped under the term stainless steel 316, e.g., 1.4404 or 1.4571. If your medium contains salts, chlorides, or acidic substances, such a material is recommended. Attention: Even seemingly harmless media such as well water can exceed critical limits and pose corrosion risks. A water analysis provides certainty here. Read more about selecting the right material.

2. Ensure adequate venting and breathing

The diameter of the vent or breather valve must be at least equal to the outlet size of the vessel to prevent the formation of a vacuum or overpressure. The valve’s flow rate must match the tank filling rate. If the venting capacity is lower than the discharge speed, the tank can implode – especially if the valve is blocked or defective. Regular maintenance is therefore essential.

3. Train your personnel in tank operation

Even if operating a tank seems simple, damage often occurs when untrained employees step in. Therefore, create a clearly structured operating and maintenance manual and attach it visibly to the tank. This ensures that even substitutes know exactly which steps must be taken and in what order.

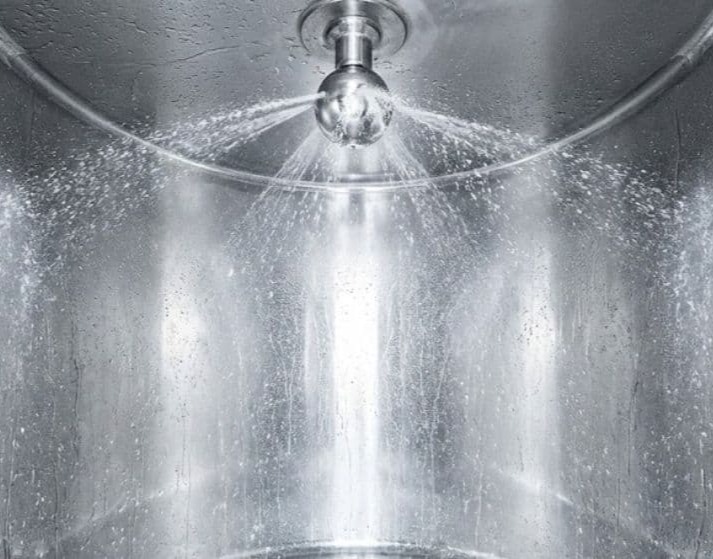

4. Take care during CIP cleaning

After cleaning with hot media, the tank should be given sufficient time to cool before being filled with cold media. Otherwise, an implosion may occur – especially if the breather valve is not adequately sized. Venting ensures that the volume changes caused by steam condensation are balanced.

5. Never run agitators dry

Agitators with mechanical seals must generally not be run dry, as they rely on the medium for lubrication. This is particularly true for side-mounted agitators in the vessel shell. Therefore, always monitor the fill level of your medium.

6. Clarify documentation requirements before purchase

Before purchasing a stainless steel tank, clarify with all parties involved which technical documentation is required. For large outdoor tanks, this may include a structural stability certificate, and for pressure vessels, the corresponding test documents. For used vessels, we offer, for example, material testing using an X-ray spectrometer or food safety certificates.

Example: Vessel implosion due to insufficiently sized venting

¿Desea obtener más información sobre este servicio?

Póngase en contacto con nosotros.