¿Cuál es la viscosidad de tu producto? Tabla y recomendaciones prácticas para seleccionar tanque y agitador

La viscosidad describe la resistencia al flujo de líquidos y gases. Cuanto mayor es el valor, más espeso (menos fluido) es el medio; cuanto menor, más fluido. Para líquidos, la viscosidad aumenta a medida que disminuye la temperatura. Por ello, la viscosidad debe considerarse siempre junto con la temperatura correspondiente.

Para seleccionar el agitador adecuado o un tanque mezclador apropiado, conocer la viscosidad del medio es clave. La tabla de viscosidad a continuación ofrece valores de referencia prácticos para una amplia gama de líquidos, ayudando a clasificar rápidamente el medio.

Por cierto: el término “viscosidad” proviene del jugo pegajoso de las bayas del muérdago (Viscum), utilizado históricamente para fabricar adhesivos —de ahí que “viscoso” signifique “pegajoso”.

Briefly Explained: Dynamic Viscosity (mPas)

Dynamic viscosity (η) is usually expressed in mPas (1 mPas = 1 cP). It influences, among other things, impeller geometry, motor power, seal concept, pump type, and the required heating/cooling capacity.

How to Use the Table

- Identify the medium and its temperature (adjust/convert if needed).

- Compare the viscosity range with similar media (for orientation).

- For sizing an agitator/tank: provide viscosity + temperature range + solids/particle content.

Need support? Contact us – we will recommend a suitable agitator and the right tank for your medium.

Viscosity Table (by Category)

Food & Beverages

| Medium | Temperature | (dyn.) Viscosity [mPas] |

|---|---|---|

| Apple sauce | 20 °C | 1,500 |

| Gravy | 80 °C | 110 |

| Fruit mash | 20 °C | 600 |

| Fruit juice | 20 °C | 50 |

| Fruit juice concentrate | 20 °C | 2,500 |

| Gelatin | 45 °C | 1,200 |

| Vegetable soup | 20 °C | 430 |

| Glucose | 25–30 °C | 4,300–6,800 |

| Yogurt | 40 °C | 150 |

| Condensed milk | 40 °C | 80 |

| Condensed milk, sweetened | 20 °C | 6,100 |

| Liqueurs | 20 °C | 10–100 |

| Milk | 20 °C | 2 |

| Pudding | 40 °C | 1,000 |

| Cream (30–50% fat) | 20 °C | 15–115 |

| Foam dessert | 40 °C | 1,500 |

| Processed cheese | 60 °C | 30,000 |

| Chocolate sauce | 50 °C | 280 |

| Tomato ketchup | 30 °C | 1,000 |

| Tomato paste | 20 °C | 195 |

| Sugar solution 65°Bx | 20 °C | 120 |

| Sugar solution 70°Bx | 20 °C | 400 |

Oils & Fats

| Medium | Temperature | (dyn.) Viscosity [mPas] |

|---|---|---|

| Cottonseed oil | 20 °C | 60 |

| Honey | 40 °C | 2,000 |

| Butter | 40 °C | 30,000 |

| Butterfat | 40 °C | 45 |

| Peanut oil | 40 °C | 40 |

| Cocoa butter | 60 °C | 50 |

| Bone oil | 20 °C | 300 |

| Coconut oil | 20 °C | 60 |

| Cod liver oil | 40 °C | 35 |

| Linseed oil | 40 °C | 30 |

| Corn oil | 60 °C | 30 |

| Olive oil | 40 °C | 40 |

| Oleic acid | 20 °C | 40 |

| Palm oil | 40 °C | 45 |

| Rapeseed oil | 20 °C | 160 |

| Castor oil | 20 °C | 1,000–1,500 |

| Soybean oil | 20 °C | 60 |

| Vitamin oil | 10 °C | 4,500 |

| Whale oil | 20 °C | 100 |

Chemical Products & Solutions

| Medium | Temperature | (dyn.) Viscosity [mPas] |

|---|---|---|

| Alkyd resins | 20 °C | 500–3,000 |

| Dipropylene glycol | 20 °C | 107 |

| Printing inks | 40 °C | 550–2,200 |

| Glycol | 20 °C | 40 |

| Glycerin 100% | 20 °C | 1,490 |

| Glycerin 100% | 10 °C | 4,500 |

| Glycerin 100% | 0 °C | 12,100 |

| Resin solution | 20 °C | 7,100 |

| Potassium hydroxide | 20 °C | 67 |

| Latex emulsion | 20 °C | 200 |

| Sodium hydroxide 50% | 20 °C | 45 |

| Paraffin emulsion | 20 °C | 3,000 |

| Polyester resin | 30 °C | 3,000 |

| Polymer solution | 20 °C | 20,000 |

| Polyol (A component) | 10 °C | 85,000 |

| Polyol, unpigmented | 20 °C | 500–5,000 |

| Starch solution, 25°Bé | 20 °C | 300 |

| Water-based paint | 20 °C | 900 |

Cosmetics & Pharma

| Medium | Temperature | (dyn.) Viscosity [mPas] |

|---|---|---|

| Baby food | 40 °C | 1,400 |

| Liquid egg | 45 °C | 150 |

| Liquid soap | 60 °C | 85 |

| Liquid wax | 90 °C | 500 |

| Hand cream | 20 °C | 8,000 |

| Jam | 20 °C | 8,500 |

| Mayonnaise | 20 °C | 2,000 |

| Pectin | 40 °C | 300 |

| Cleansing emulsion | 70 °C | 2,420 |

| Salad dressing | 20 °C | 1,300–2,600 |

| Toothpaste | 40 °C | 70,000 |

Lubricants & Industrial Oils

| Medium | Temperature | (dyn.) Viscosity [mPas] |

|---|---|---|

| Gear oil SAE 140 | 20 °C | 2,700 |

| Gear oil SAE 90 | 20 °C | 700 |

| Hydraulic oil HLP 100 | 20 °C | 300 |

| Hydraulic oil HLP 46 | 20 °C | 120 |

| Hydraulic oil HLP 68 | 20 °C | 195 |

| Machine oil, light | 20 °C | 150 |

| Machine oil, heavy | 20 °C | 600 |

| Engine oil SAE 5 | 20 °C | 30 |

| Engine oil SAE 10 | 20 °C | 50 |

| Engine oil SAE 15 | 20 °C | 130 |

| Engine oil SAE 15W40 | 20 °C | 390 |

| Engine oil SAE 15W40 | -15 °C | 3,000 |

| Lubricating oil | 20 °C | 60–200 |

| Transformer oil | 20 °C | 30 |

| Transformer oil | 10 °C | 75 |

| Turbine oil | 20 °C | 200–1,100 |

°Bx = °Brix | °Bé = °Baumé

(c) Bürkle GmbH 2020

Practice: Correctly Accounting for Viscosity in Tanks & Agitators

Agitator Design

- Impeller geometry: Low viscosity → propeller/axial; high viscosity → anchor agitator, Paravisc, double-frame anchor.

- Power & speed: As viscosity increases, torque rises – size motor & gearbox accordingly.

- Seals/bearings: High viscosities → robust shaft seals (e.g., double tandem with barrier fluid) and suitable bearing concepts.

Temperature Management

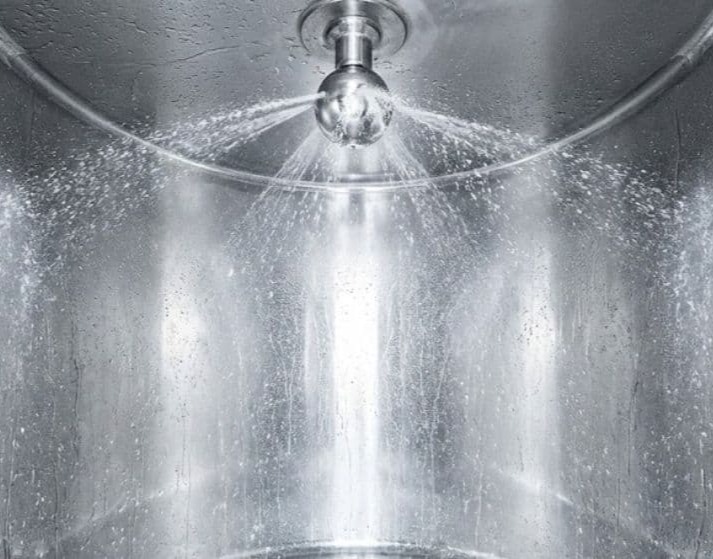

Heating/cooling jackets keep viscosity within the process window – e.g., for honey, molasses, or fats. Stable temperature lowers starting torque, shortens mixing times, and facilitates CIP cleaning.

Pumping Technology & Internal Fittings

- Pump selection: High viscosity → progressive cavity (eccentric screw) or gear pump; low viscosity → centrifugal pump often sufficient.

- Internal fittings: Baffles prevent vortex formation and improve axial flow in low-viscosity media.

Material & Surface Finish

For sticky/abrasive media, smooth stainless steel surfaces (e.g., Ra < 0.8 μm) are recommended for good discharge and hygienic cleaning. For chloride-containing media, consider stainless steel 316 grades.

Need support with the design? We will recommend the appropriate and a suitable for your medium.

¿Desea obtener más información sobre este servicio?

Póngase en contacto con nosotros.