Construcción de tanques según conformidad WHG: qué debe tenerse en cuenta

La Ley alemana de Recursos Hídricos (WHG) es un conjunto de normativas clave que regula el manejo de sustancias peligrosas para el agua. Estas sustancias pueden causar daños medioambientales considerables si no se almacenan o transportan correctamente. Por ello, existen requisitos estrictos para la fabricación, instalación y mantenimiento de sistemas de tanques conforme a la WHG. La certificación y la conformidad WHG desempeñan un papel central en este contexto.

What does the Water Resources Act regulate?

The German Water Resources Act (WHG) was introduced to protect water bodies from pollution and to create the basis for sustainable water management. The handling of water-polluting liquids, which are divided into different water hazard classes, is particularly important:

- Water hazard class 1 (WGK 1): Low water-polluting substances that can only affect water bodies in small quantities.

- Water hazard class 2 (WGK 2): Substances that can damage water and require special precautions.

- Water hazard class 3 (WGK 3): Substances that are highly hazardous to water and can cause considerable environmental damage even in small quantities.

The classification into these classes determines which safety precautions and measures are required for the storage and transportation of the substances.

Approvals and certifications

A key aspect of tank construction in accordance with the WHG is compliance with strict approval and certification standards. These include, among other things:

- WHG approval: Tank builders can be certified by the competent authority as a specialist company in accordance with the WHG and thus be authorized to manufacture WHG tanks.

- DIN and EN standards: All tanks must comply with the relevant DIN and EN standards, such as DIN 6616 for cylindrical sheet-steel tanks or EN 12285 for underground tanks. These standards guarantee mechanical stability and resistance to chemical influences.

In consultation with the responsible supervisory authority (TÜV), a tank design can also be implemented on the basis of an alternative set of regulations in order to produce a tank equivalent to the WHG regulations. In this case, production in accordance with the Pressure Equipment Directive (PED) is recommended, which also places high demands on the safety level of the system.

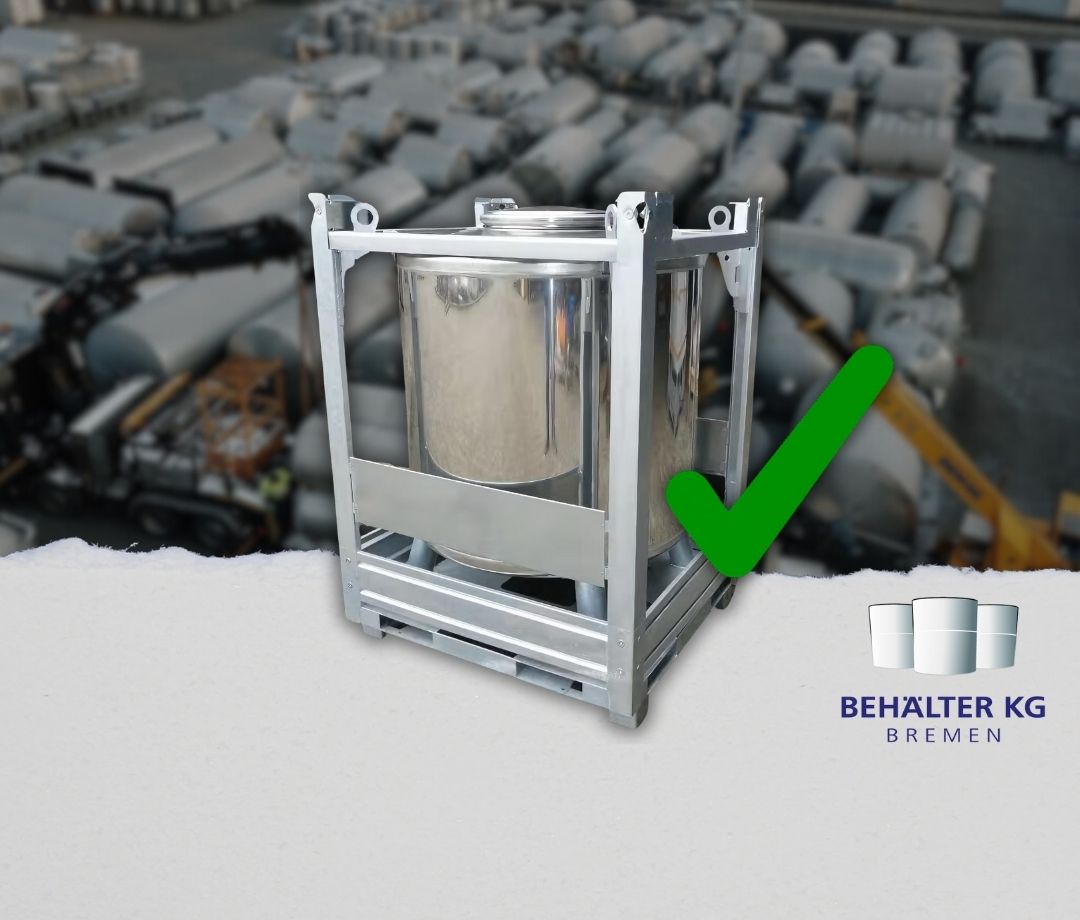

In addition to the type plate, a specialist company can also affix a so-called Ü-Zeichen (conformity mark) to the container. The Ü-Zeichen is proof that the container or the design has been manufactured in accordance with the recognized rules of technology and meets the legal requirements.

Types of WHG tanks

A variety of designs can generally be realized in compliance with WHG. The most common designs can be summarized as follows:

- Single-walled above-ground storage tanks (horizontal) according to EN 12285-1 (formerly DIN 6616-1).

- Double-walled above-ground storage tanks (horizontal) according to DIN 6616-2.

- Double-walled underground storage tanks (horizontal) according to EN 12285-1 (formerly DIN 6608).

- Single-walled above-ground storage tanks (upright), based on the former DIN 6618-1.

- Double-walled above-ground storage tanks (upright), based on the former DIN 6618-2.

The exact requirements and permissible designs may vary depending on the federal state and specific application, so it is important to observe the relevant local regulations and guidelines.

Technical features of WHG tanks

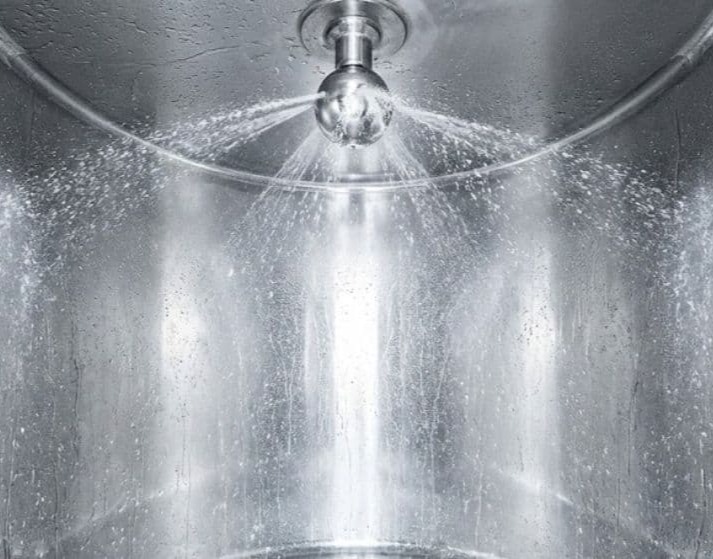

WHG tanks have various safety features to prevent leaks and environmental damage as far as possible. This can include the following, for example:

- Leak detection systems: Monitor the interstitial space in double-walled tanks or pressure/vacuum changes and alert early in case of leakage.

- Overfill prevention devices: Prevent the tank from overflowing and minimize the risk of contamination.

- Venting devices: Compensate pressure differences and ensure safe filling and emptying.

- Double-walled construction: Provides an additional protective barrier so that hazardous liquids do not escape into the environment in the event of a leak.

- Sump trays: Serve as secondary containment to collect escaping liquids and prevent contamination of the ground.

- Reinforcements: Internal reinforcements increase structural integrity and stability.

- Periodic inspections: Tanks must be inspected by a recognized expert at least every five years.

The production of WHG-compliant tanks requires a high level of technical expertise and strict compliance with legal regulations. Meeting these requirements makes a significant contribution to the safe storage of water-polluting substances.

¿Desea obtener más información sobre este servicio?

Póngase en contacto con nosotros.