Tanques de acero inoxidable usados como almacenamiento térmico: eficiencia y sostenibilidad para la industria y la energía

En procesos industriales y en centrales de biomasa suele acumularse calor excedente que a menudo no se aprovecha. Los tanques de acero inoxidable usados ofrecen una solución eficiente: como tanques tampón, acumuladores de calor o depósitos estratificados, pueden almacenar temporalmente el calor y liberarlo cuando sea necesario. Esto ahorra energía, reduce las emisiones de CO₂ y disminuye los costes.

Heat Storage with System: Buffer Tanks in Industrial Use

Whether in the food and chemical industry or in the pharmaceutical and energy sectors – buffer tanks compensate for fluctuations between heat supply and demand.

Example: A large dairy uses waste heat from production, stores it in a 300,000-liter stainless steel tank, and feeds the heat into two networks. Result: 15% higher energy efficiency and noticeable savings on electricity and fuel.

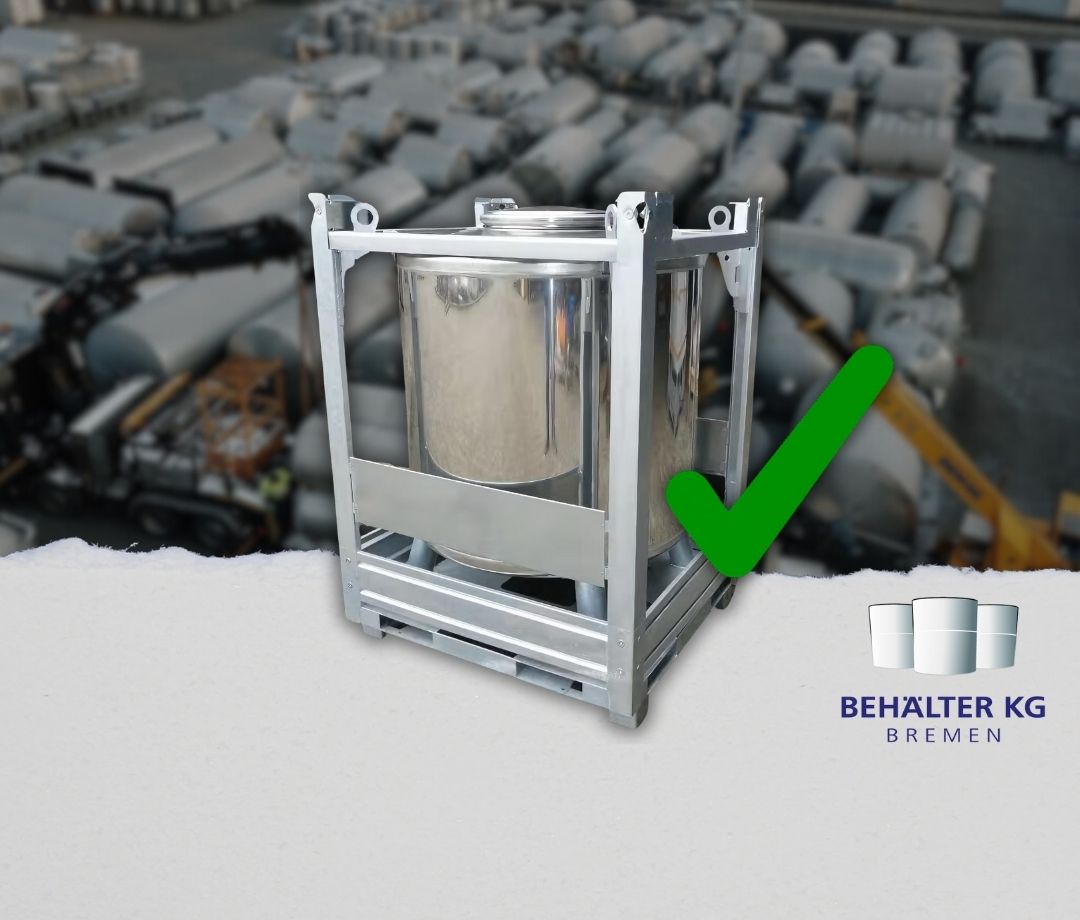

Why Used Stainless Steel Tanks?

- High quality and durable: Stainless steel is corrosion-resistant, hygienic, and temperature-resistant.

- Cost-efficient: Used tanks are often immediately available and significantly cheaper than new products.

- Sustainable: Reuse saves up to 5 tons of CO₂ per tank – through saved materials and manufacturing effort.

Many suppliers professionally refurbish used tanks: cleaning, pressure testing, fittings, and insulation included. This creates economical heat storage solutions for projects starting from about 10,000 liters in volume – ideal for medium to large applications.

Pressurized and Non-Pressurized Solutions

Depending on temperature and system requirements, heat storage tanks are designed as pressurized (closed) or non-pressurized (atmospheric) vessels.

- Pressurized tanks: Suitable for temperatures above 100 °C and closed heating systems.

- Non-pressurized storage: Ideal for lower temperatures, e.g. in district heating or solar thermal systems.

Stainless steel stands out for its durability – even with oxygen ingress.

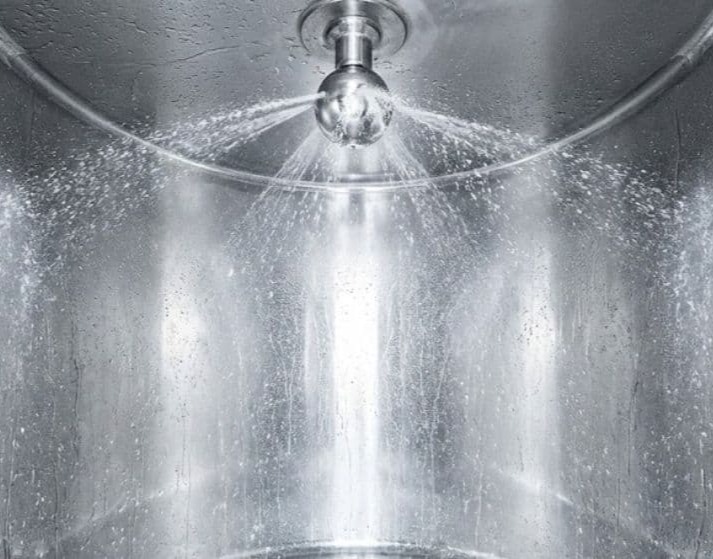

Stratified Storage: Distributing Heat Efficiently

Through temperature stratification, a storage tank can simultaneously provide heat at different levels. In biomass power plants, this enables efficient load management: hot water is available at the top for peak demands, cooler water is reheated at the bottom.

Stainless steel tanks in a vertical design are particularly suitable for this type of heat distribution.

Practical Application Examples

- Dairies & Breweries: Process heat from pasteurization or cleaning is buffered and reused.

- Chemicals & Pharmaceuticals: Discontinuously generated heat can be stored and used in subsequent process steps.

- Biomass Power Plants: A 200,000-liter storage unit in Kelheim saves around 62 tons of CO₂ annually and enables demand-driven heat usage.

Modular storage solutions with multiple tanks (e.g. 3 × 50,000 liters) are also possible – for example, when space is limited or heat is generated in stages.

Advantages at a Glance

- Energy efficiency through heat recovery

- Cost advantages through reuse & lower investment costs

- Climate protection through CO₂ savings & circular economy

- Flexibility in size, pressure level, and equipment

Conclusion

Used stainless steel tanks are more than just a cost-effective alternative – they are a key element for sustainable, economical, and future-proof energy systems. From medium-sized food producers to municipal energy providers: the reuse of high-quality tanks as heat storage units is worthwhile.

¿Desea obtener más información sobre este servicio?

Póngase en contacto con nosotros.